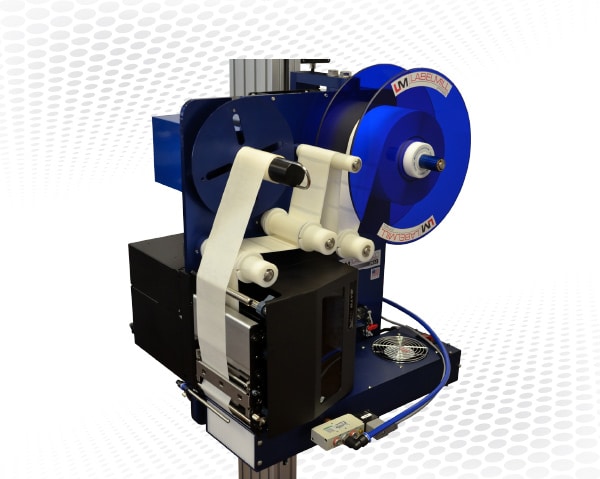

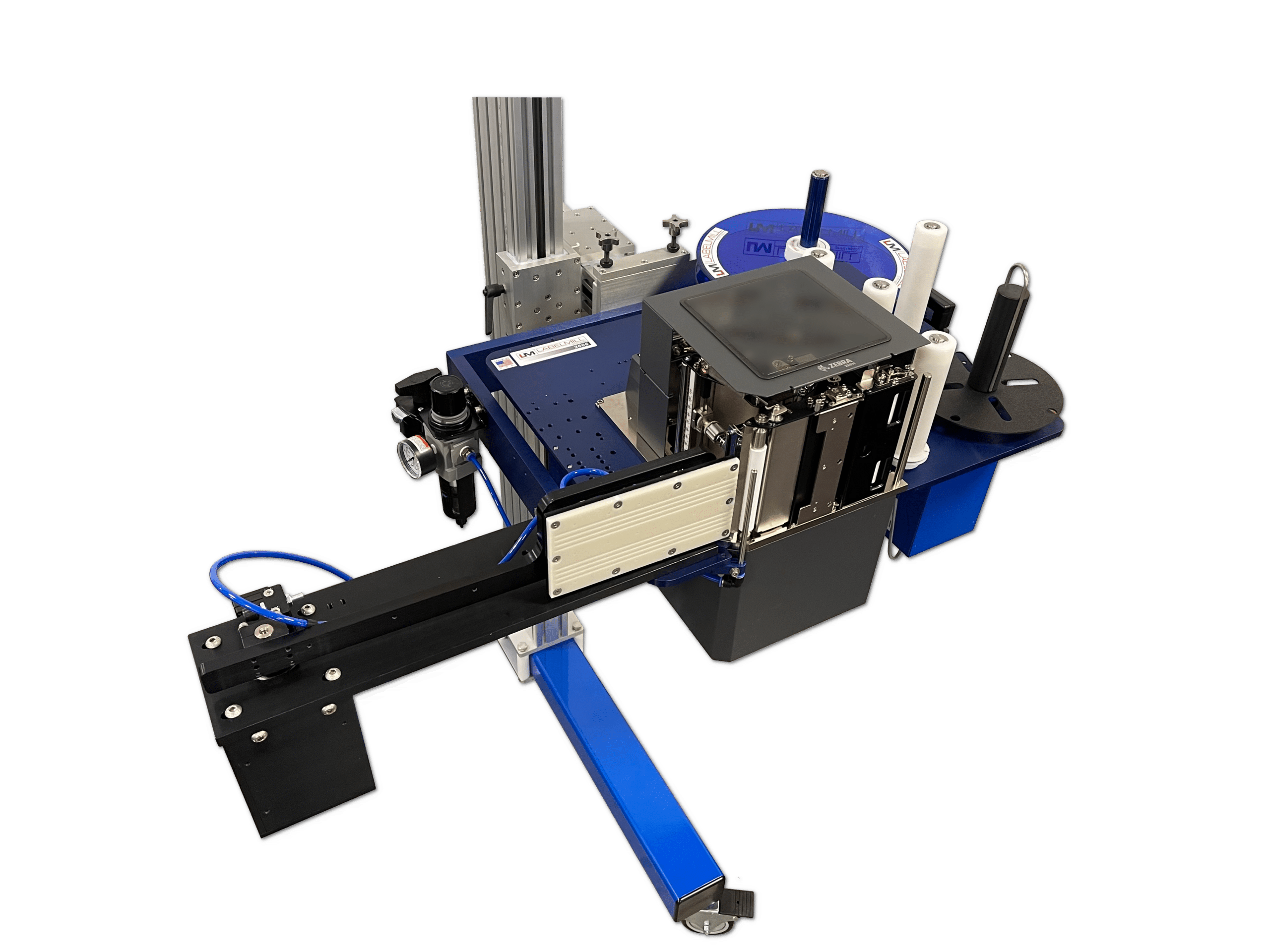

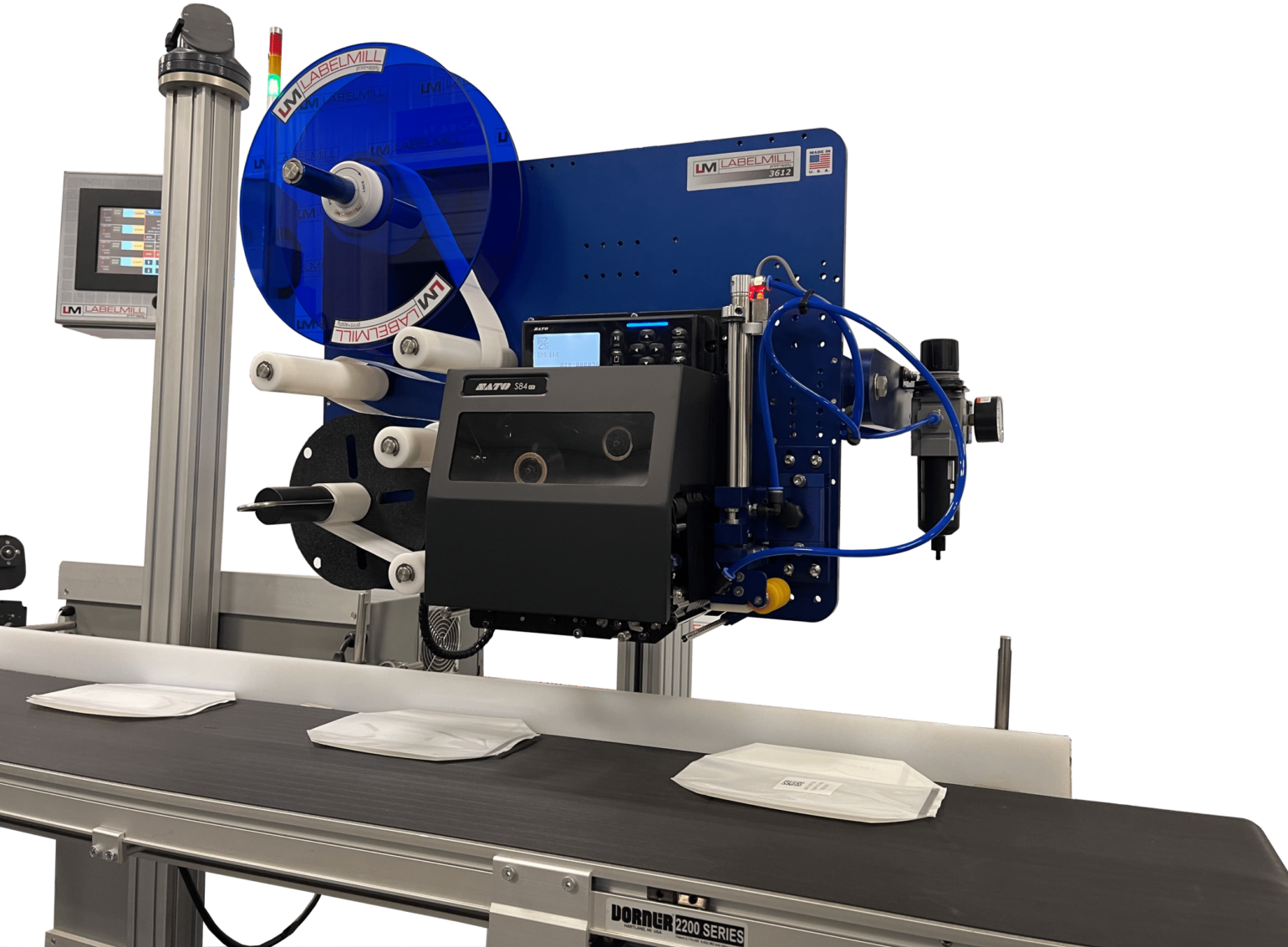

A high-performance print and apply label system designed for seamless integration into high-end production processes with faster speeds and extensive I/O points can significantly enhance automation capabilities.

LM3612APL

Labeling Speed/Rate: Up to 16” per second and, depending on label and product size, approximately 10 to 90 per minute

Print Method: Thermal transfer and direct thermal

Interface: Centronics parallel, RS-232c Serial, Ethernet, Wireless, USB

Bar Codes: UPC-A, UPC-E, EAN-8, EAN-13, CODE 3912/5, CODE 128, CODABAR, MSI, 2/5, CODE 93, UPC Bookland, Matrix 2/5, POSTNET, UCC/EAN 128, PDF-417, Maxicode, Data Matrix

Bar Code Ratios: 1:2, 1:3, 5:2

Interface Sensors: Product sensor-photo eye/limit switch/PLC input Auxiliary output with connector standard

Electrical: 115 VAC/60Hz – 250 W idle, 600 running

Human Readable Fonts: 12 proportional and mono-spaced fonts including OCR-A and OCR-B representations and an outline font. American and European characters, uppercase and lower case with descenders (code table 850)

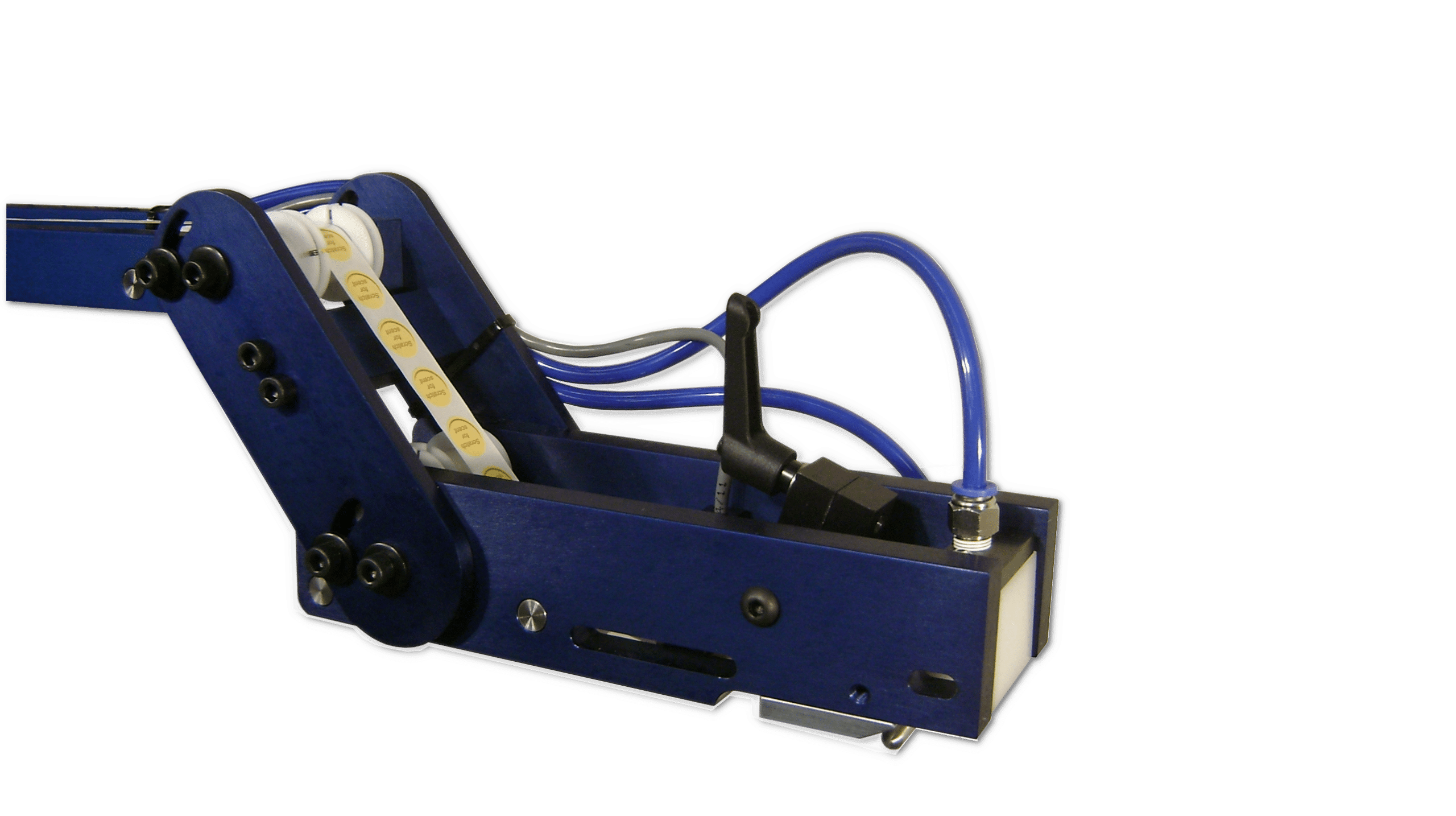

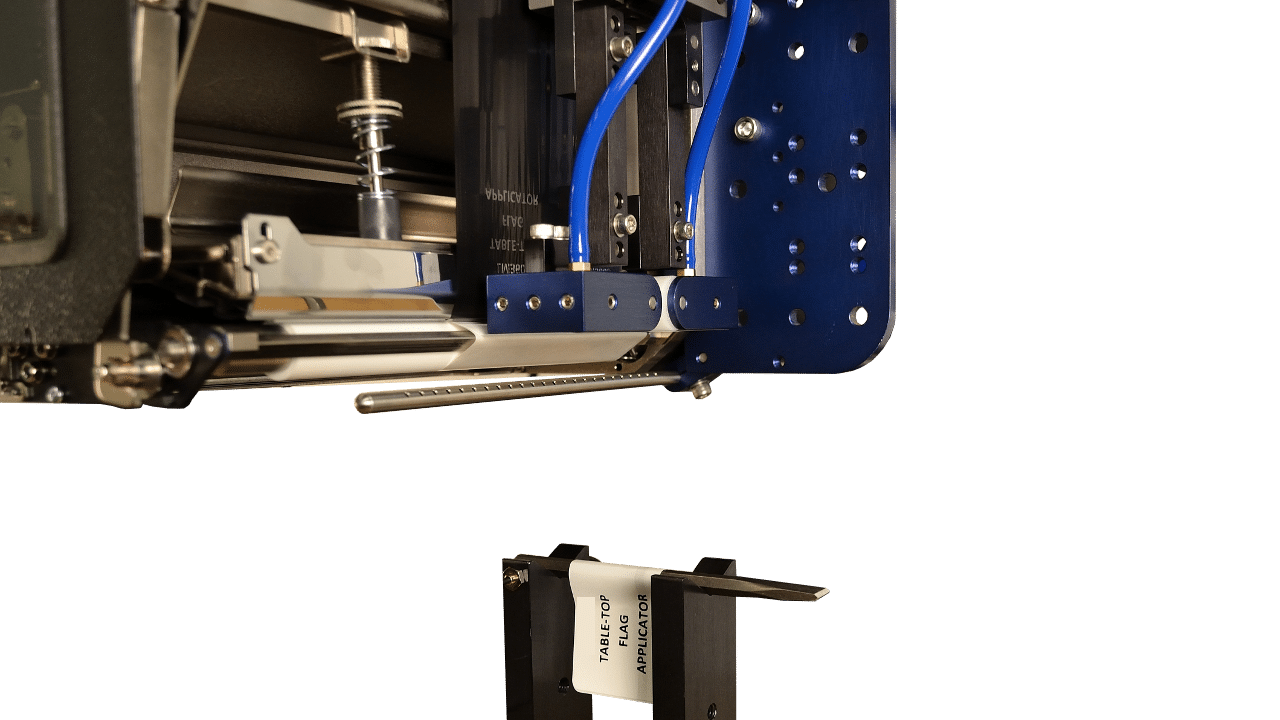

Air Requirements: 80 psi/3 cfm when equipped with tamp, flag, blow, swing, or corner wrap

Environment: Operating 50-95° F (10-35° C) 15-85% RH, non-condensing

Label Size: Minimum 1” wide x 1/2” long

General Size: 25”W x 22”D x 21”H

Weight: 61 lbs. with u-arm

Label Roll Capacity: 12” maximum outside diameter wound on a 3” I.D. core. Die-cut waste removed with minimum of 1/8” separations between labels in running direction.