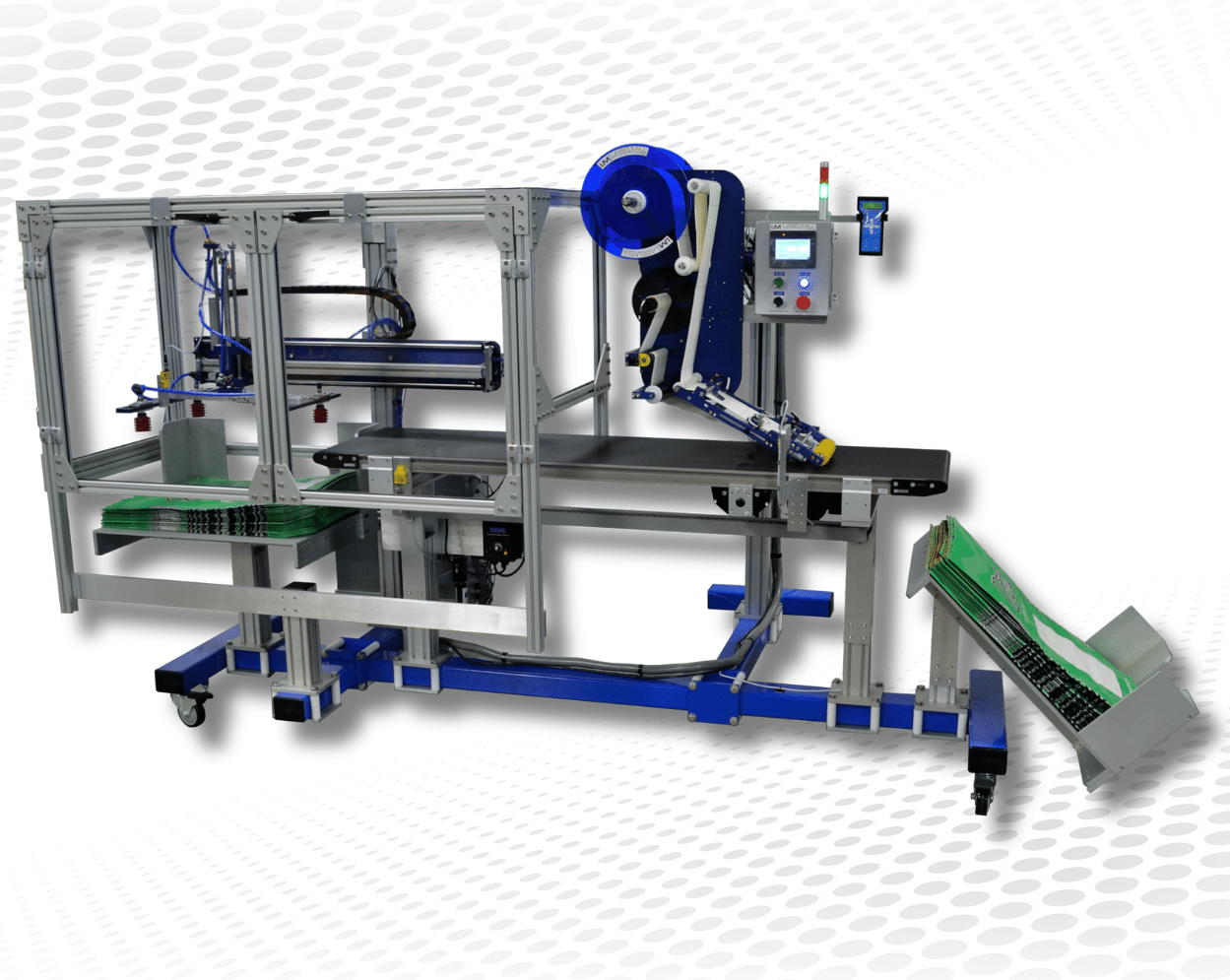

Pick & Place Bag Feeder System with Label Applicator

LM5000BF

The LabelMill LM5000BF is a pick-and-place bag feeder combined with an automatic label applicator, designed for efficient and precise bag labeling to handle flat products, pouches, and large bags in mid‑ to high‑volume operations. It reliably feeds and spaces bags at rates of approximately 8–30 units per minute (product‑dependent), with label placement accuracy within ±1/16″. Built on a heavy‑duty mobile frame with touchscreen controls, it can work as a standalone or integrate seamlessly with an existing production line.

Benefits:

Designed to streamline operations, the LM5000BF Bag Feeder Labelling System automates the feeding and labeling of large bags and flat products—reducing manual labor and increasing throughput. Its precise label placement and compatibility with multiple application methods deliver consistent, professional results. With flexible configuration options and easy integration, this label applicator is ideal for growing production demands without compromising accuracy.