Semi-Automatic

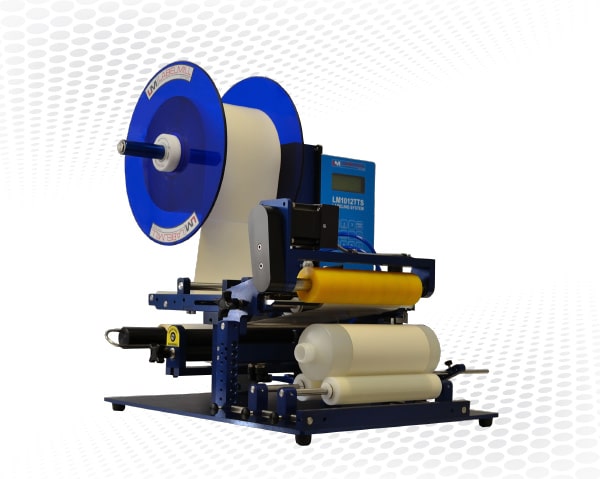

LM1012

Semi-Automatic Table Top Label Applicator

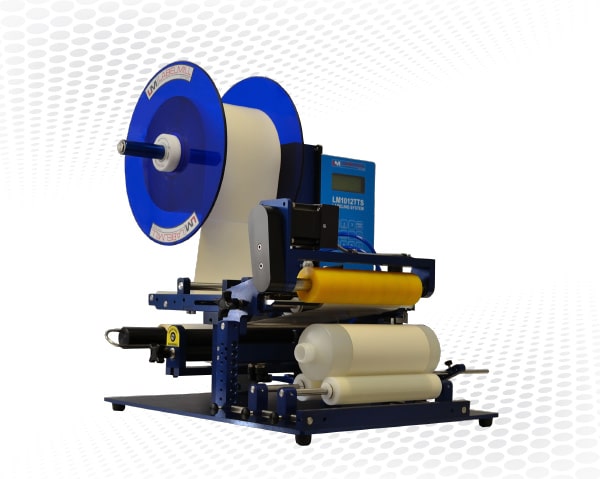

LM1012RM

Semi-Automatic Table Top Label Applicator for round products

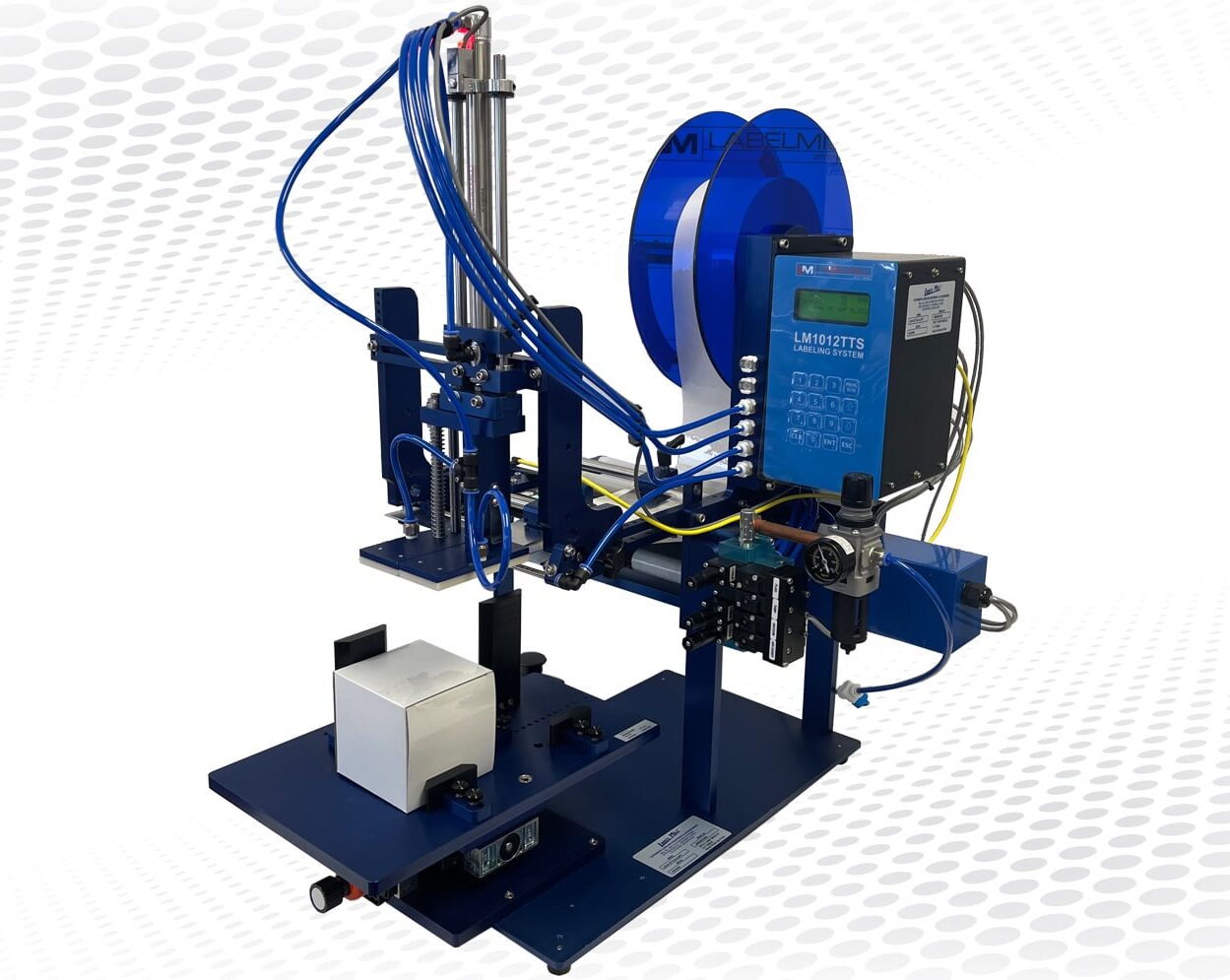

LM1012TM

Semi-Automatic Table Top Label Applicator

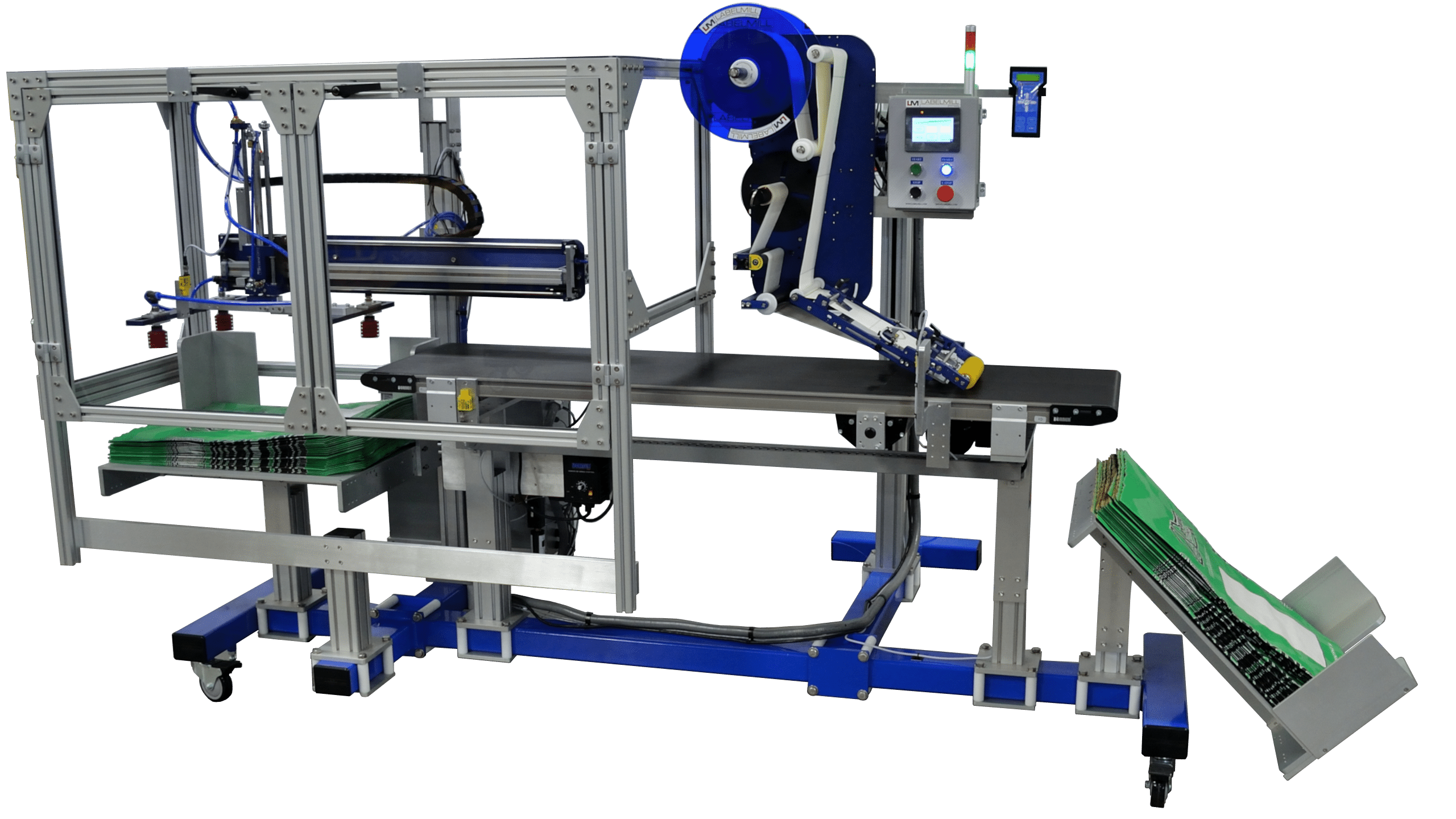

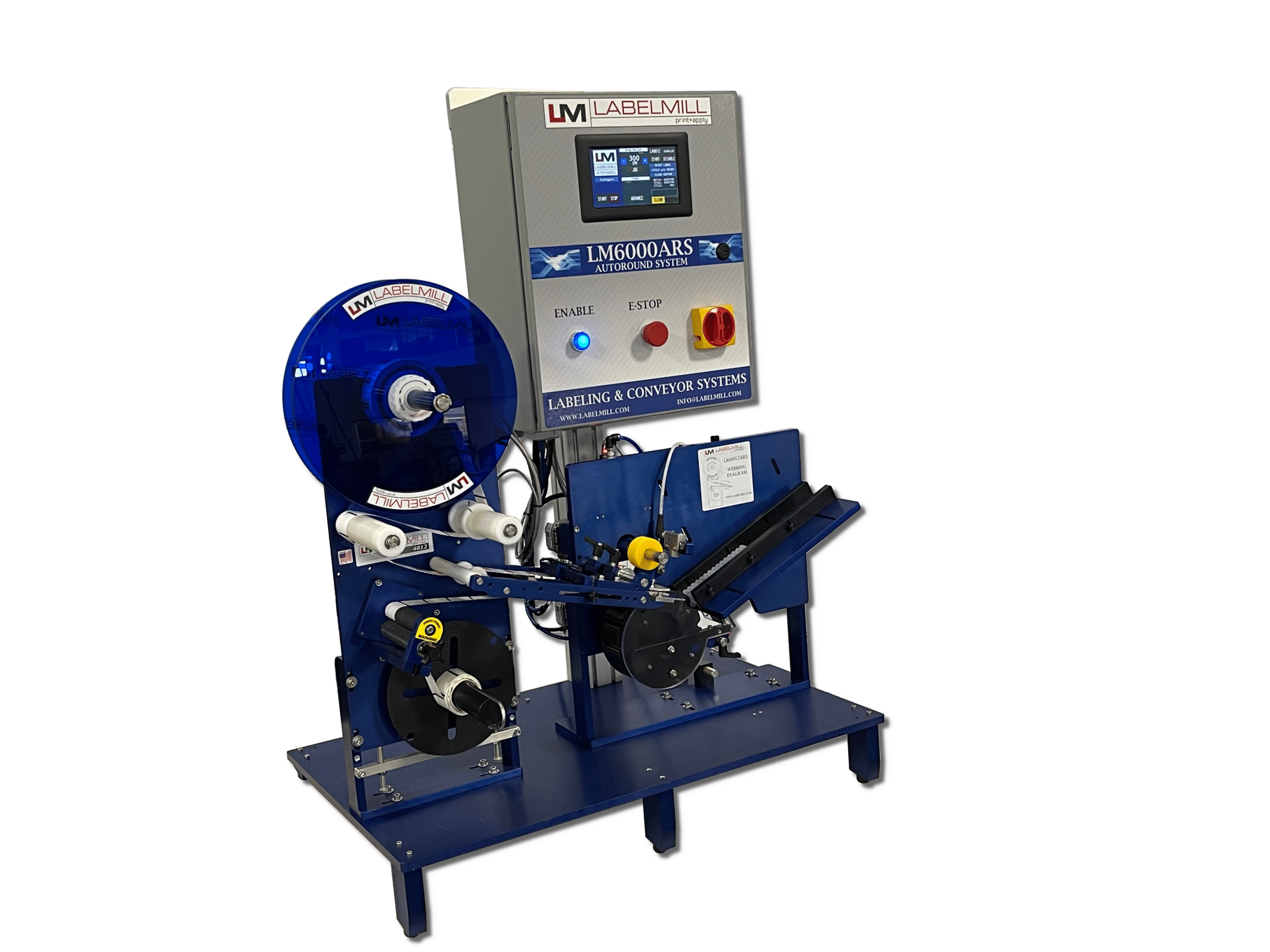

LM6000ARS – LM4012

Semi-Automatic Table Top Label Applicator

Semi-Automatic Print & Apply

LM3612CTTST

Split Tamp Semi-Automatic Print + Apply

LM3612CTT

Semi-automatic table top color print + apply label applicator

LM4012TTPAS

Semi-automatic loose-loop print & apply table top label applicator

LM1012LL

Semi-Automatic Loose Loop Label Applicator

Automatic Apply

LM4012

Entry Level Hybrid Servo Drive Label Apply Only Applicator

LM1512

High-speed full servo drive apply only label applicator

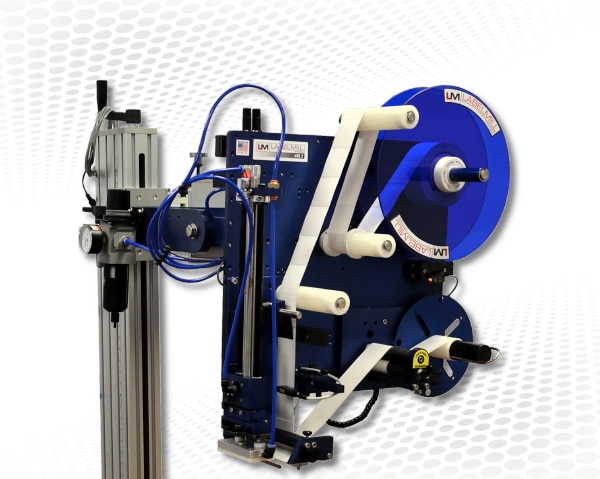

Automatic Print & Apply

LM3606

Print and Apply Label Applicator

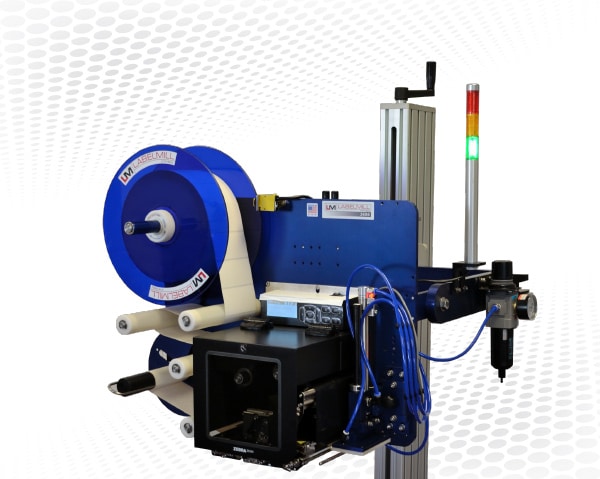

LM3612

High-performance print and apply label applicator

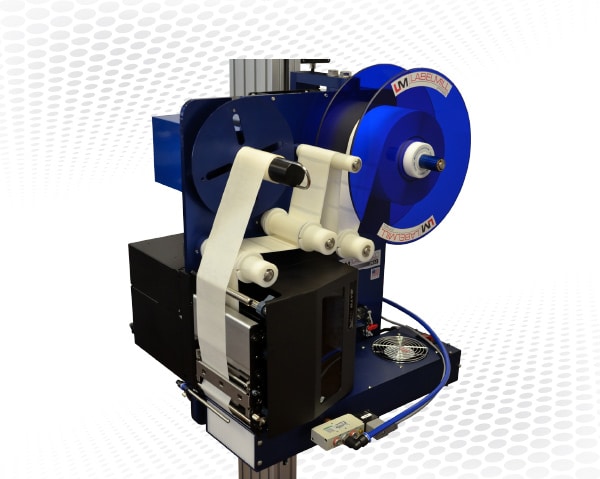

LM3542SF

Closed loop print & apply label applicator

LM3562SF

Closed loop print and apply label applicator

Label Applicator Conveyor Systems

Don't see what you're looking for?

Contact Us to Inquire about our Custom Options

Let's Talk about your Labeling Needs