300% Faster and More Efficient Product Labeling

The Challenge

As demand for cannabis products continues to grow, manufacturers and distributors often struggle to keep up, especially when processes such as product and container labeling are still performed manually.

At one cannabis producer, manual labeling of pre-roll tubes was slowing down production and impeding its ability to meet customer demand. The manual process involved printing variable information on labels with a desktop printer and then hand-applying the labels to the pre-roll tubes.

Multiple employees were handling this slow and cumbersome process at a rate of 10-12 pieces per minute per employee. Due to occasional mistakes in the process, many labels and tubes went to waste when the labels were applied crooked or wrinkled.

The company wanted to solve these problems with automated labeling that would speed up and error-proof the process, but the uniquely round shape of pre-roll tubes and the nature of the packaging process posed a challenge for traditional print-and-apply labeling systems.

The Solution

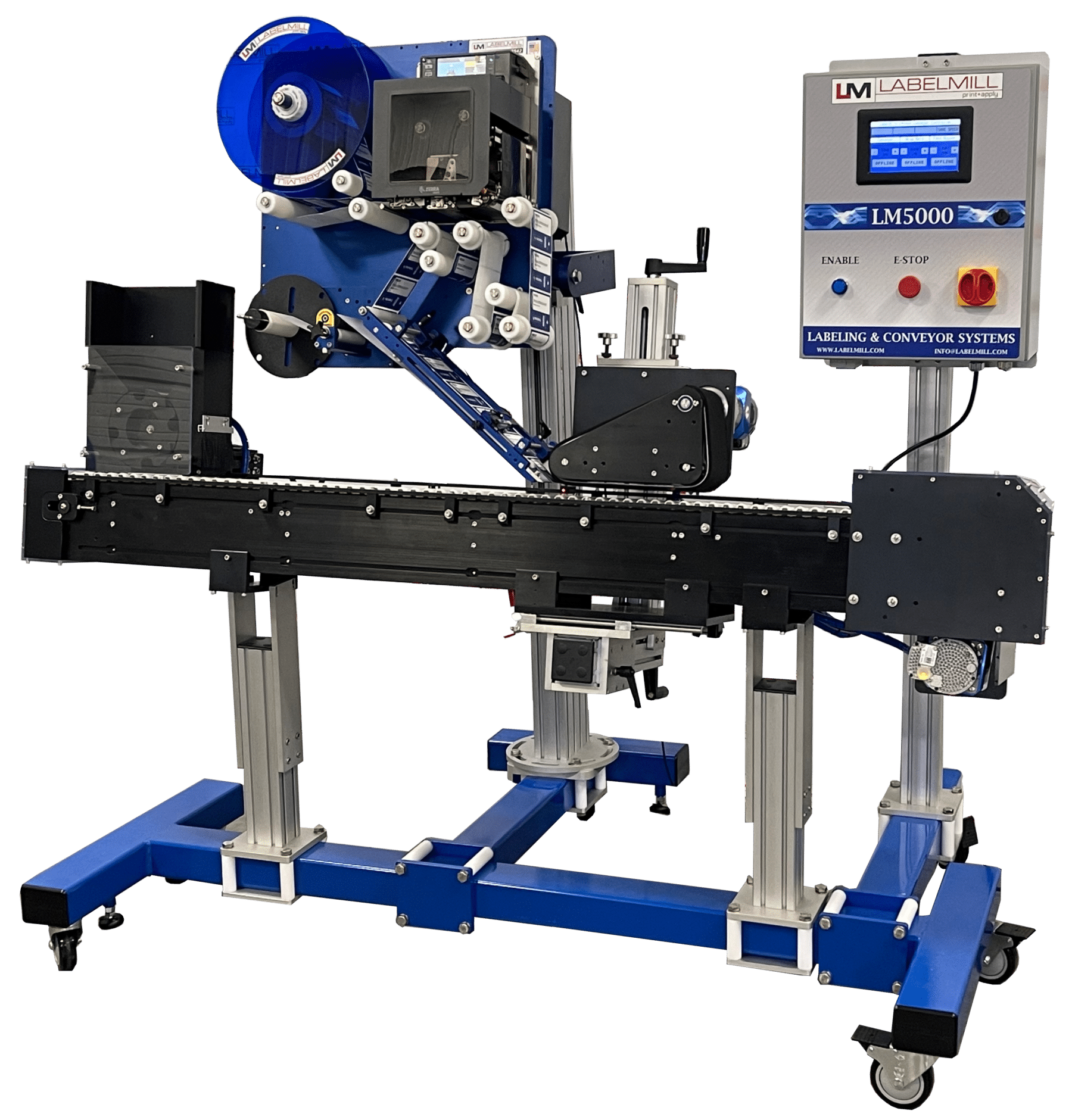

The cannabis producer reached out to LabelMill, a leader in labeling automation solutions for over 40 years. LabelMill has extensive experience in designing and building custom labeling equipment at its in-house facility in Illinois, so its experts quickly got to work and developed a pre-roll tube labeling system using a roller-bed conveyor and a print-and-apply label applicator.

The system automatically prints and applies labels to up to 60 pre-roll tubes at a time, using a powered hopper that allows an operator to load batches of tubes. As batches are loaded, tubes are automatically dispensed onto a roller-bed conveyor with precise spacing.

A Zebra ZE511 print engine prints and feeds each label, and a synchronous feed module then dispenses the label between the conveyed tube and a powered wrap-belt assembly to apply the label to the tube. Once tubes are labeled, they’re automatically dropped into a collection bin for the operator to gather in batches.

The system is turnkey and was easy to install at the cannabis producer’s production facility. The applicator provides both vertical and horizontal hand-crank adjustments, if needed. It is also extremely simple, using modular components, an interface and controls that user friendly and easy to service and maintain.

SYSTEM COMPONENTS

- LabelMill, LM5000RB Roller-Bed Conveyor

- LabelMill, LM3542SF Print-and-Apply Label Applicator

- Zebra ZE511 Print Engine

- Powered hopper and catch bin

The Results

- 300% faster labeling vs. the old manual process

- Automatic, precise and accurate labeling of each tube

- Automated system with operator control over batches

- Reduction in production labor requirements and costs

- Reassignment of manual labor to other value-added tasks

Once the new pre-roll tube labeling system was installed, results were achieved on day one. The automated system increased labeling speed and efficiency by 300% compared to the previously manual process. A 60-tube batch capacity and print speeds of 60 to 80 tubes per minute ensure that labeling is extremely fast. But an operator still maintains complete control over labeling and the volume of each batch.

Labels are also applied precisely and consistently for maximum quality and reliability, so there’s no risk of human error or variance in labeling. Also, since the company no longer needs multiple employees to be assigned to manual labeling, it was able to reallocate those resources to other required tasks.

Additional Applications

LabelMill’s tube-labeling and other automated systems can be adapted and customized for other industries and applications, including labeling of tubes and other types of containers and packaging for medical, health and pharmaceutical products.

Since each LabelMill system uses modular components and can be custom-designed to meet specific requirements, you can work with experts to design and build a solution for virtually any labeling need. Plus, there are standard LabelMill systems available to match common labeling applications and requirements in many use cases.