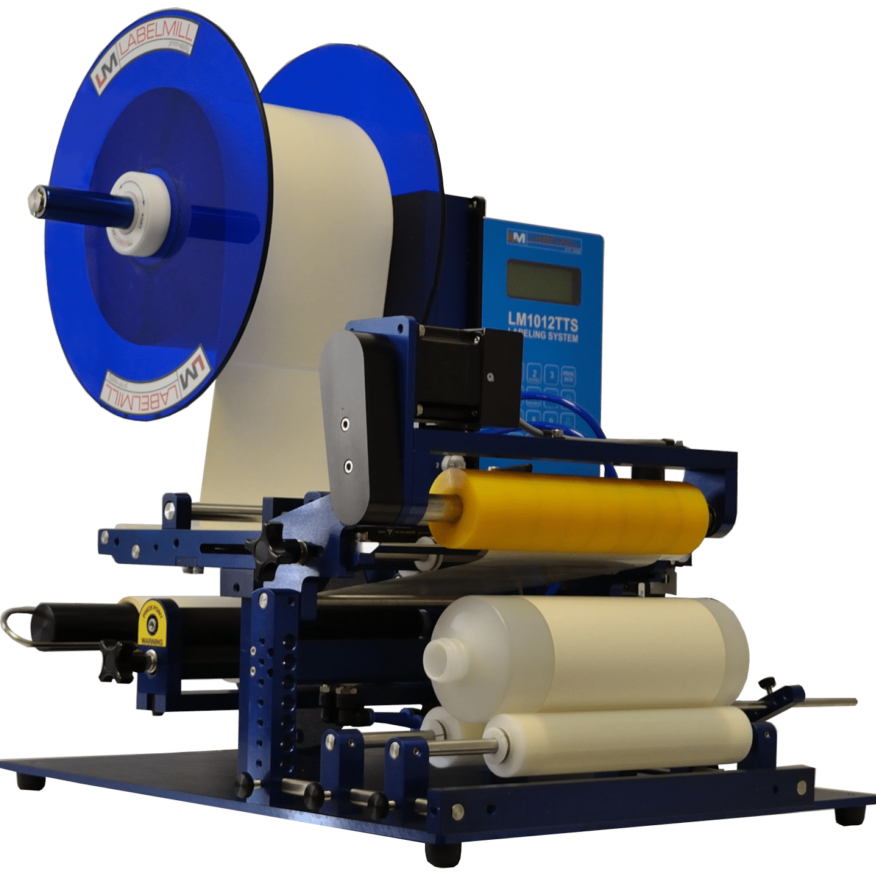

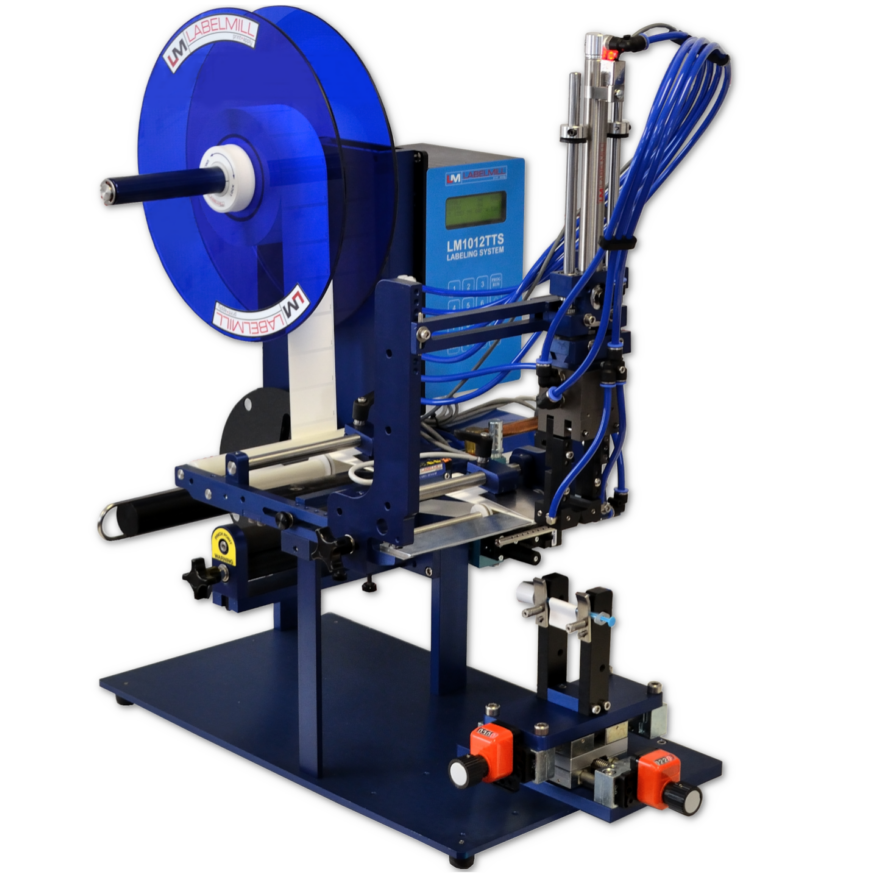

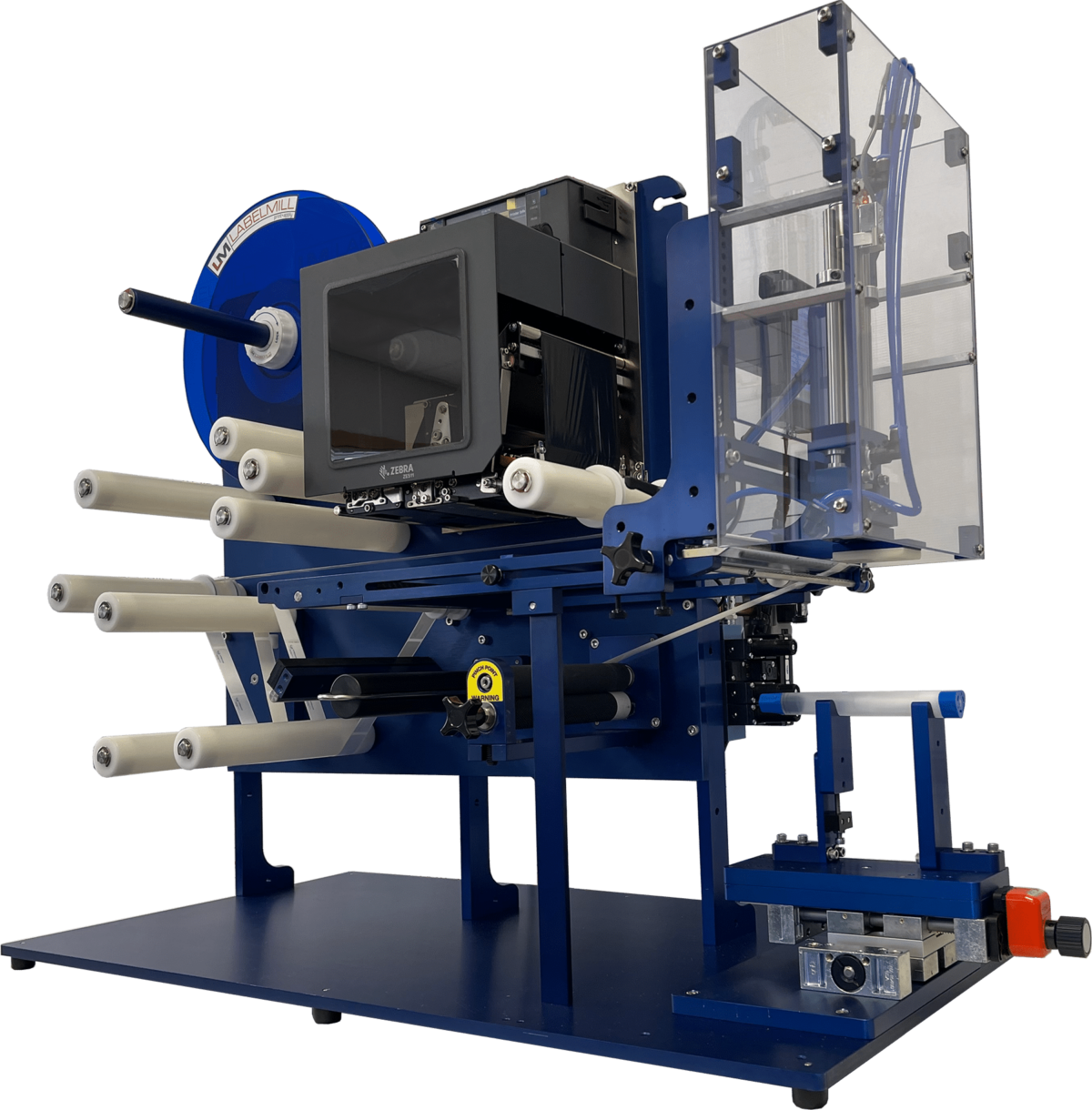

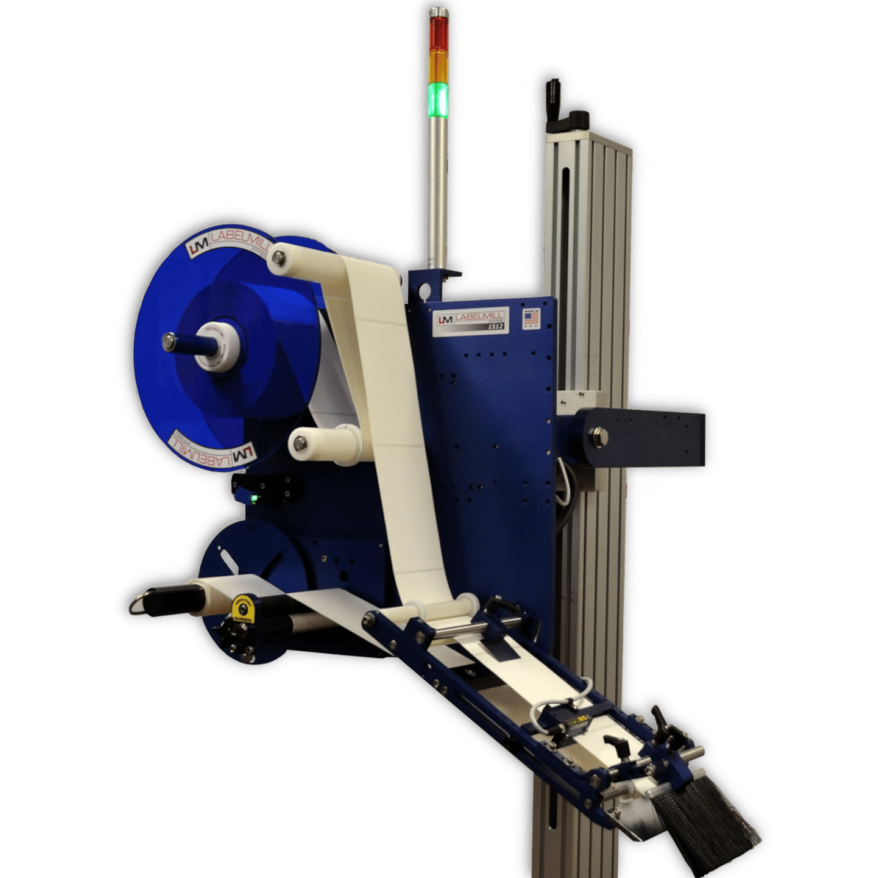

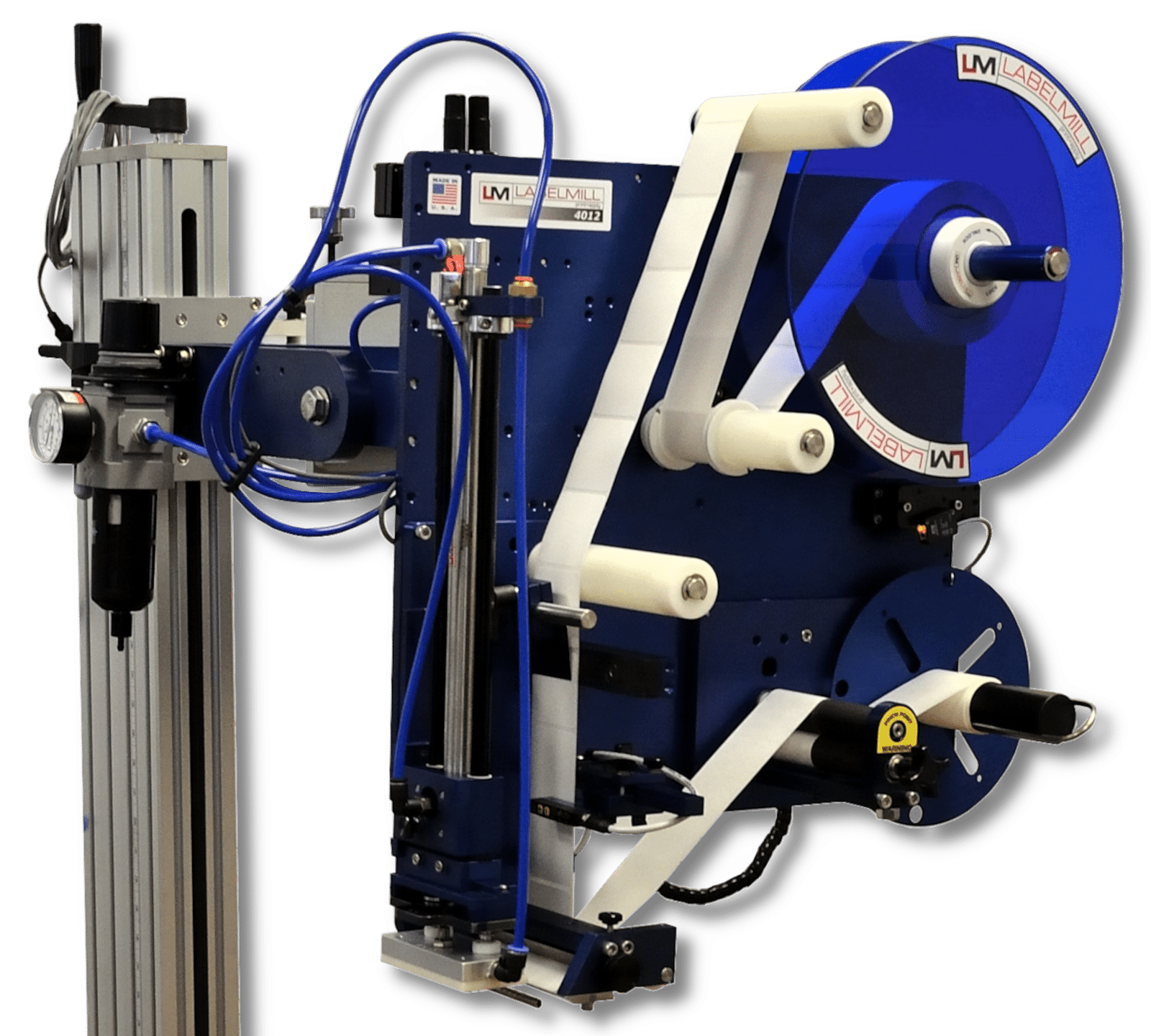

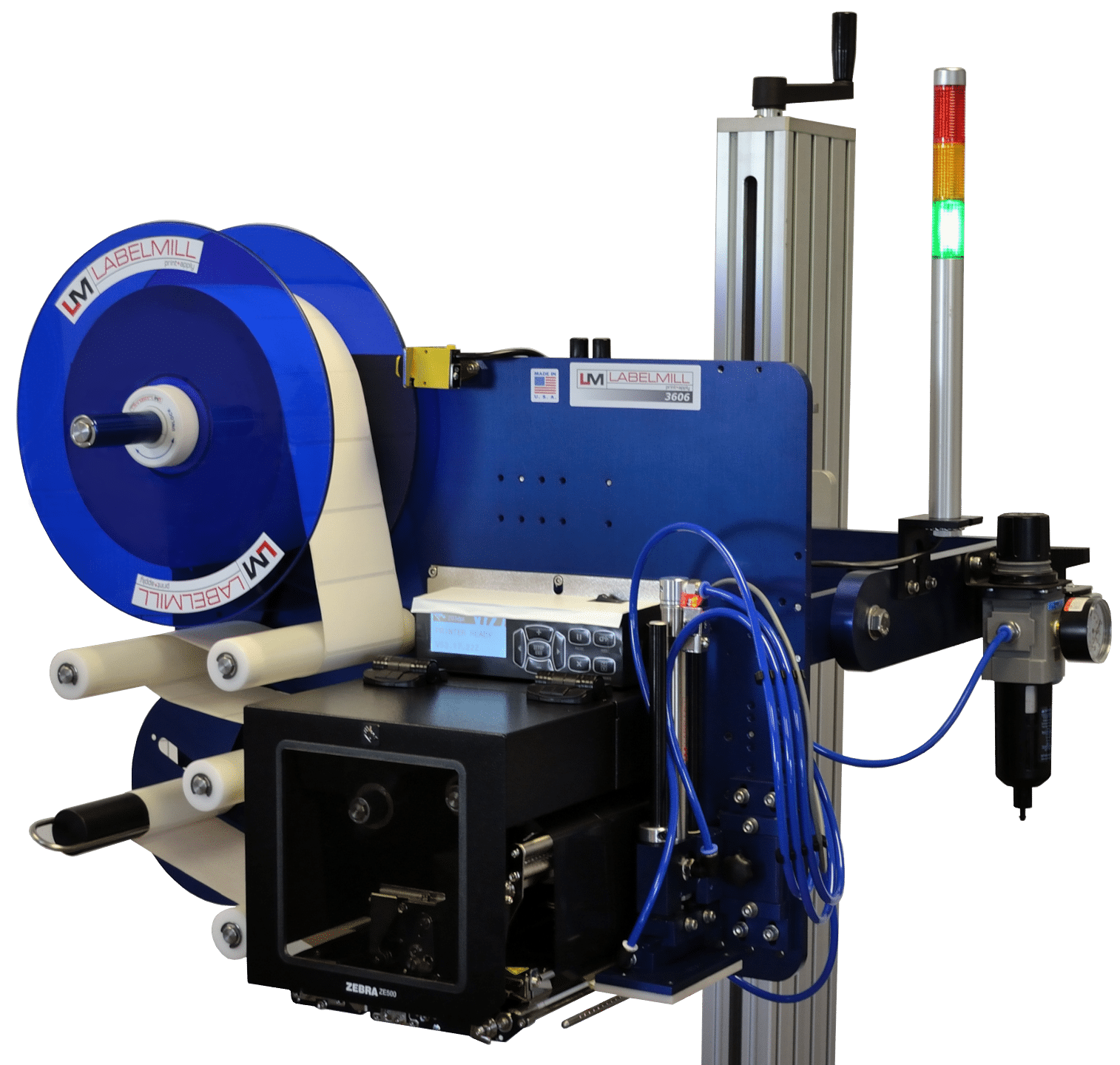

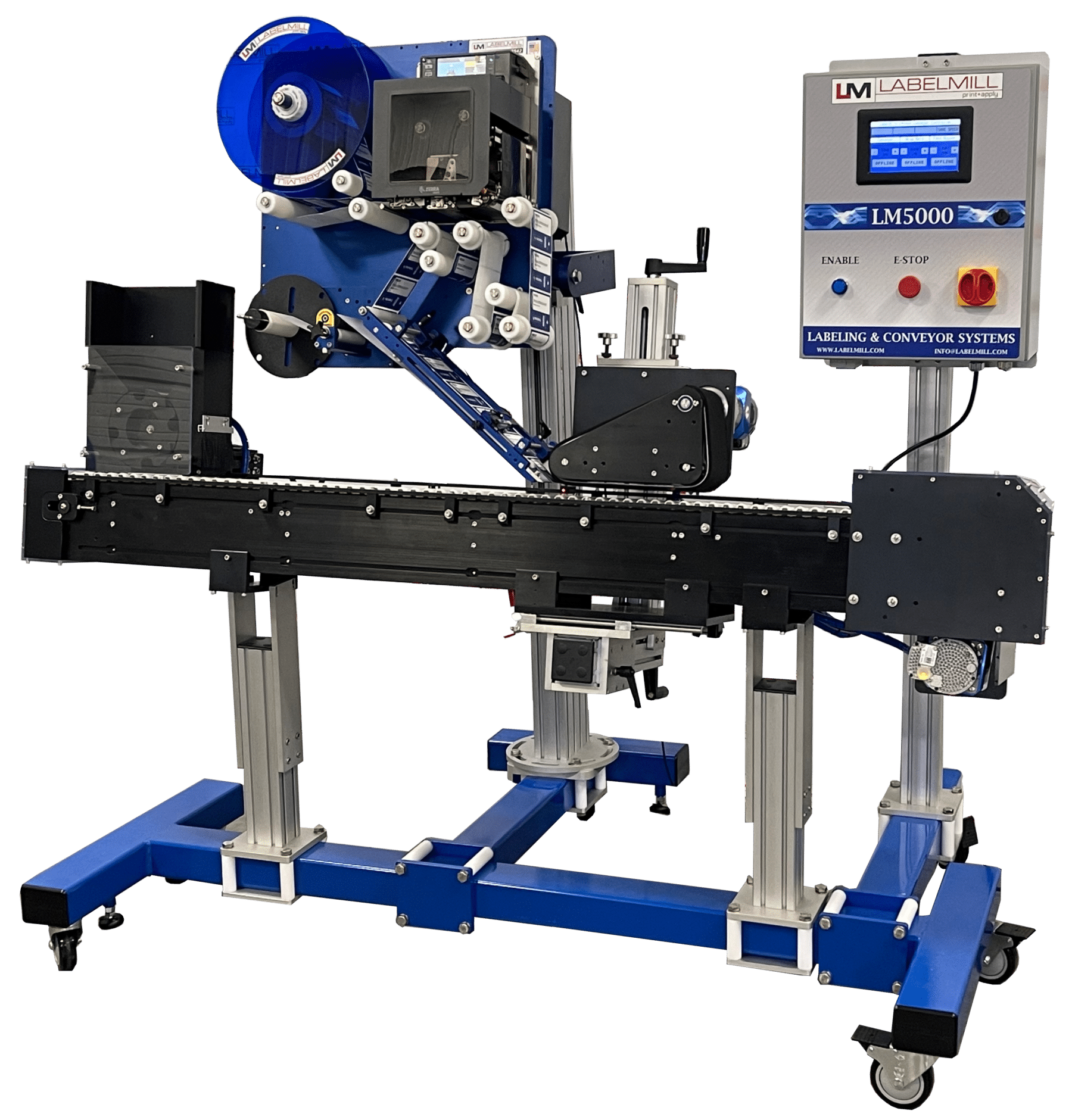

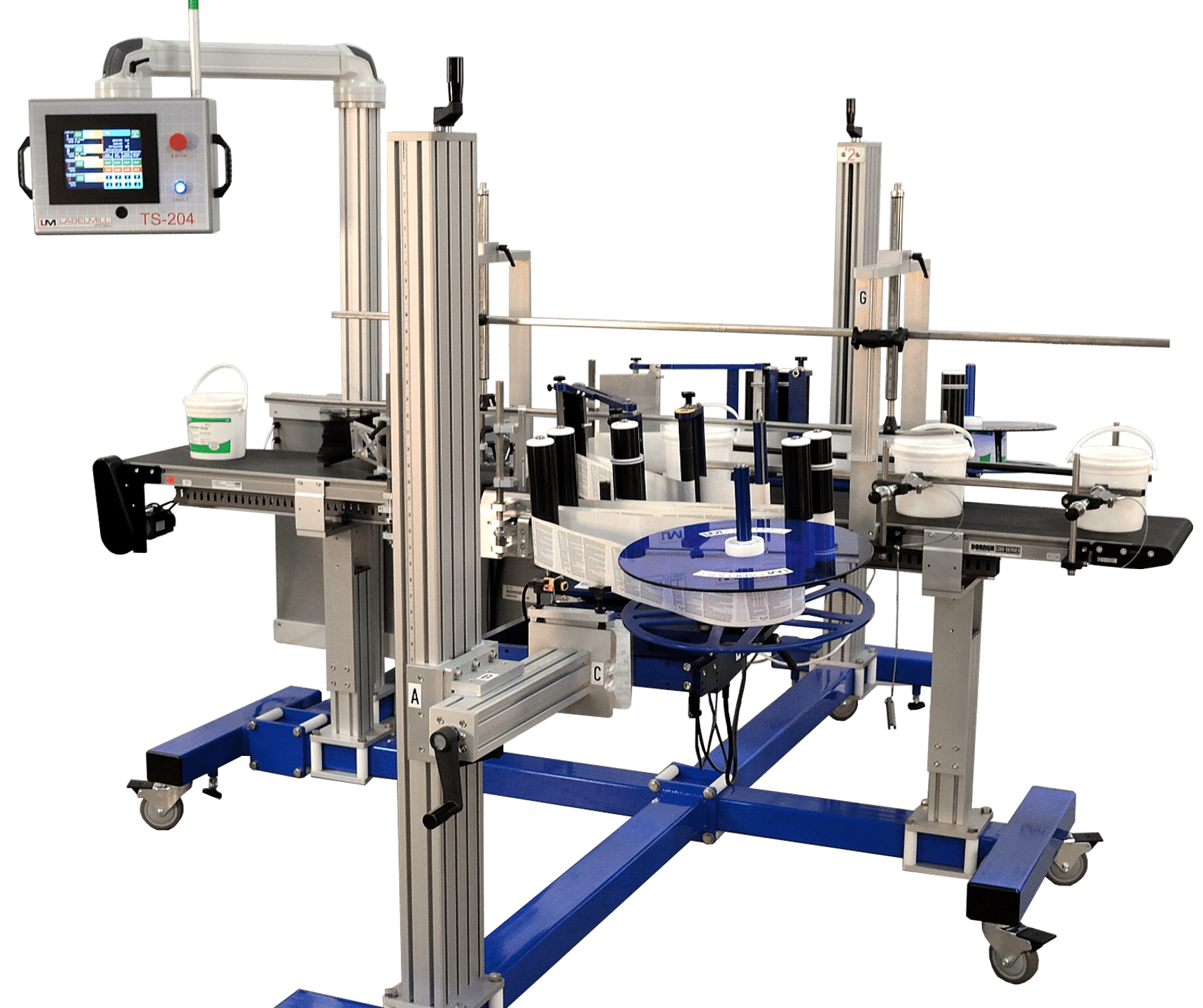

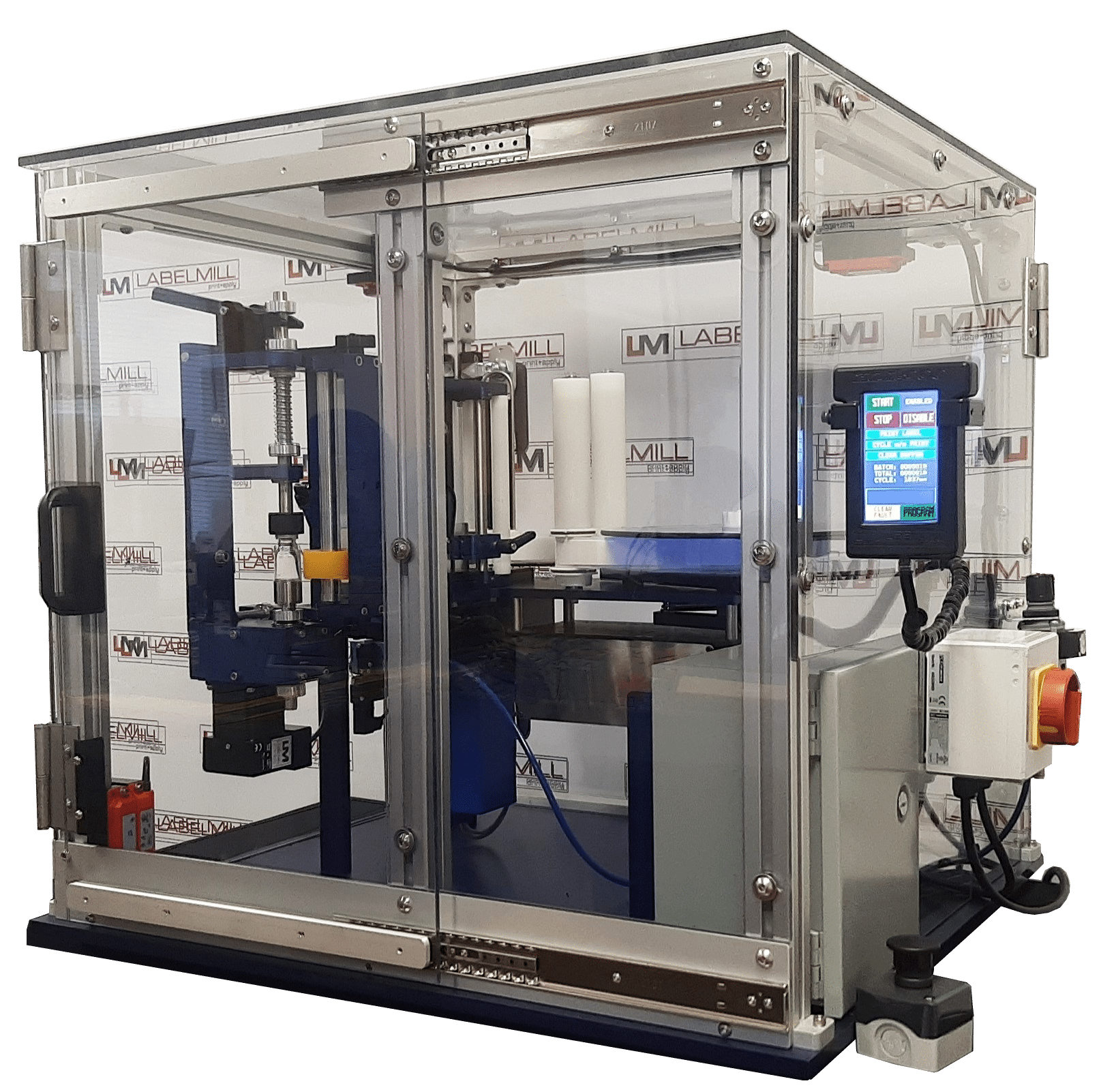

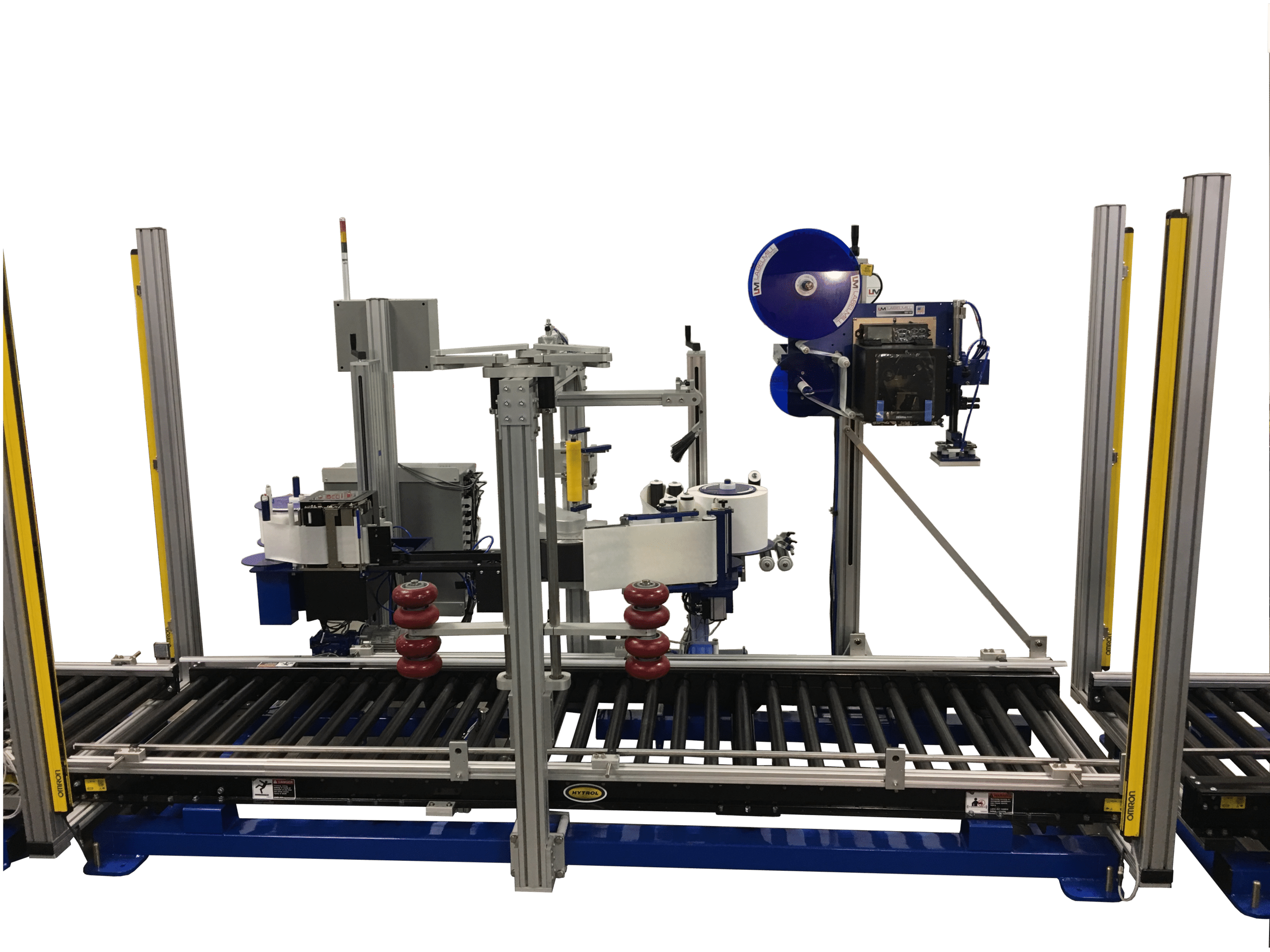

LabelMill offers versatile solutions for applying shipping labels, seamlessly catering to diverse packaging types, from bags to boxes. Our innovative systems ensure efficient and accurate label application, meeting your specific needs with precision.

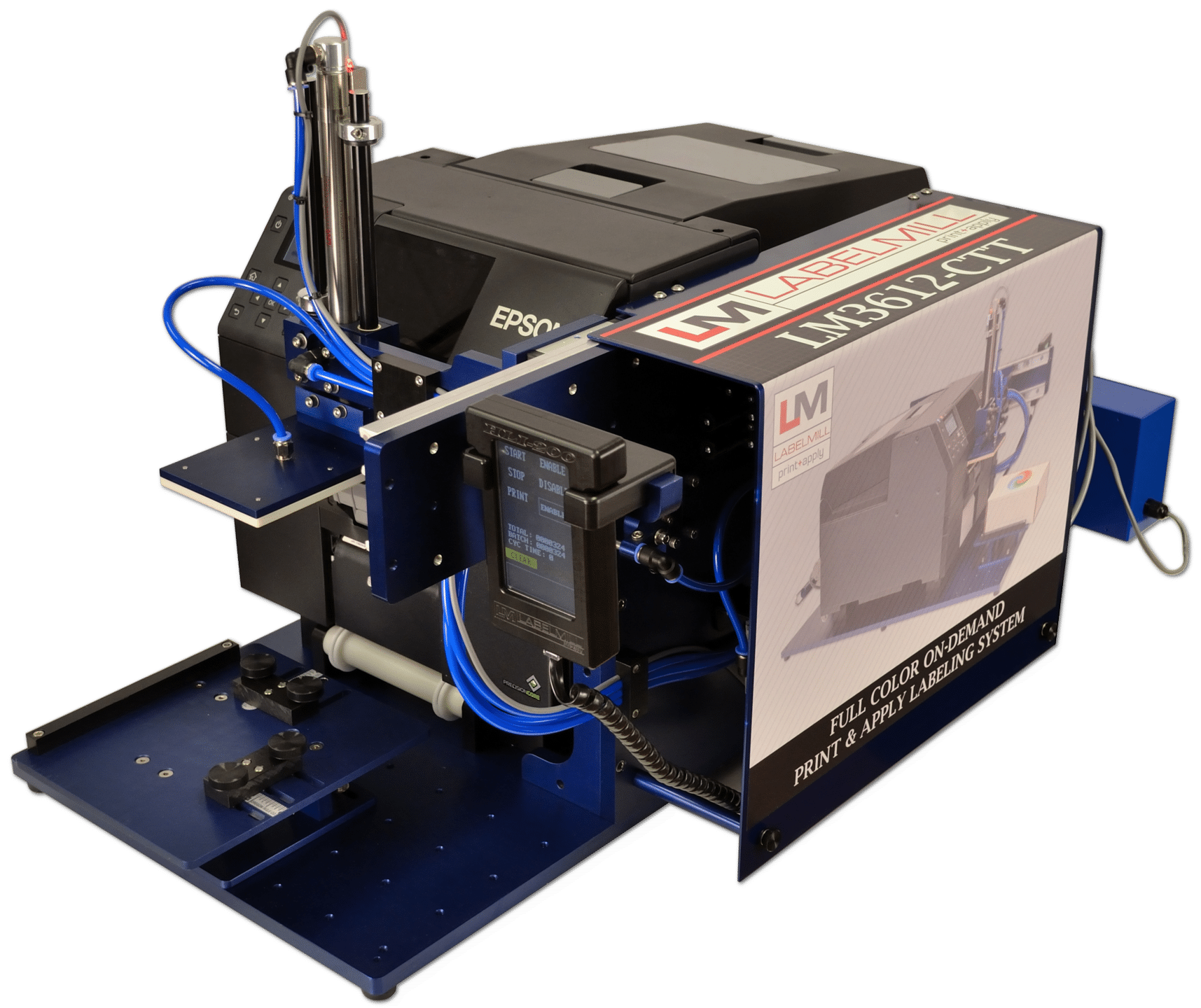

Don't see what you're looking for?

Contact Us to Inquire about our Custom Options

Let's Talk about your Labeling Needs