Print and apply label applicator that is cost-effective and designed for entry-level automation with flexibility to meet production.

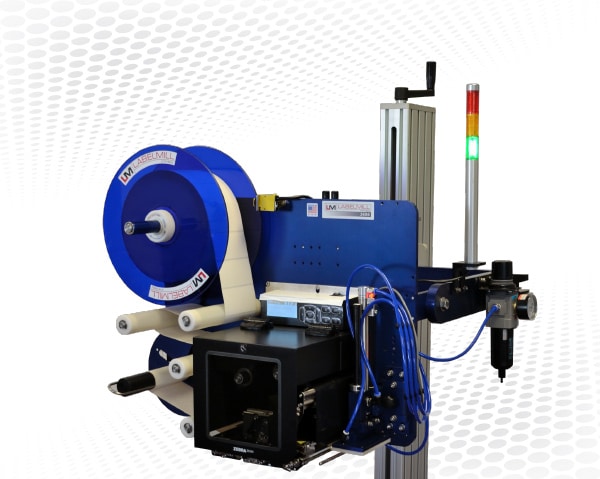

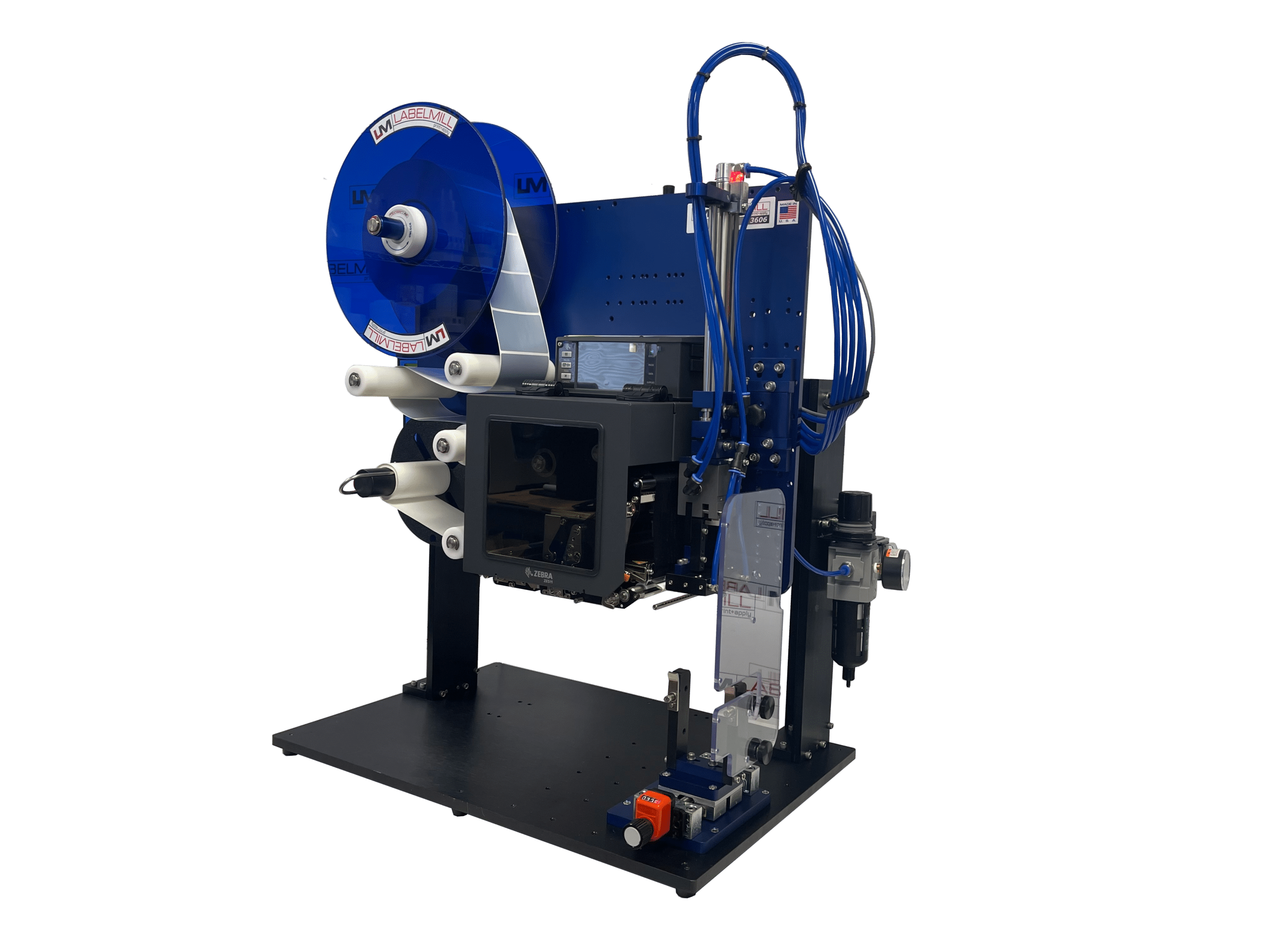

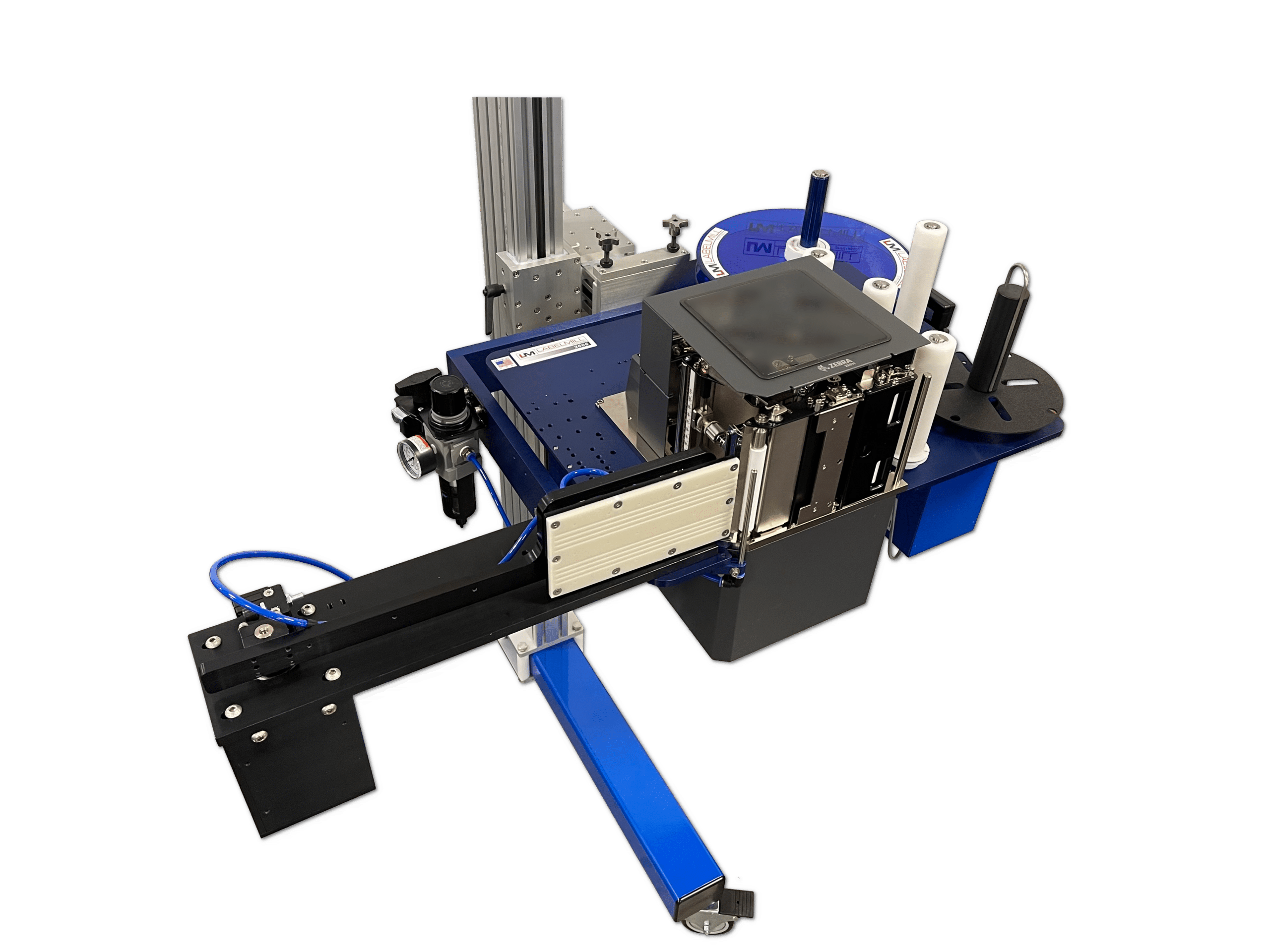

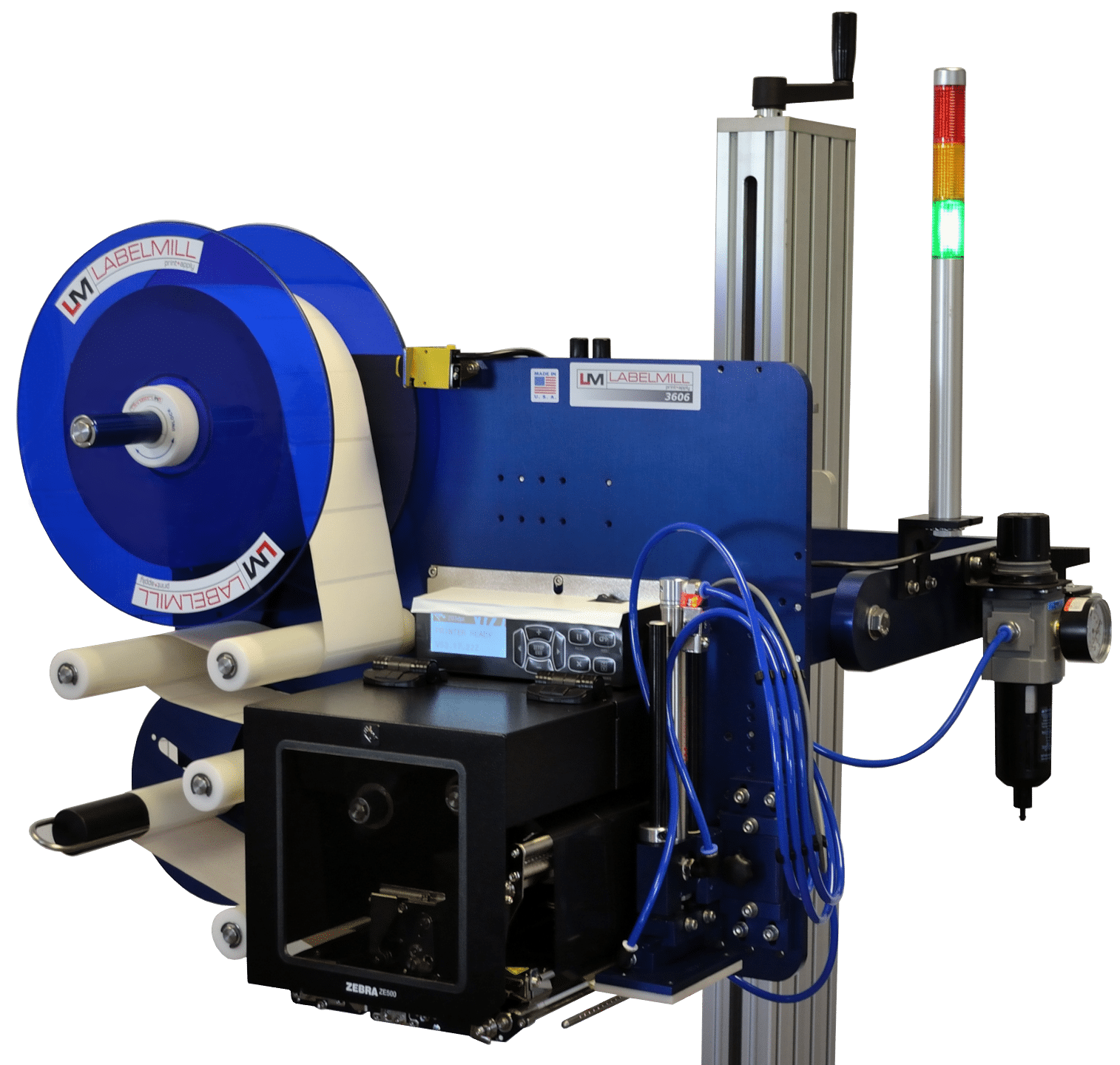

LM3606

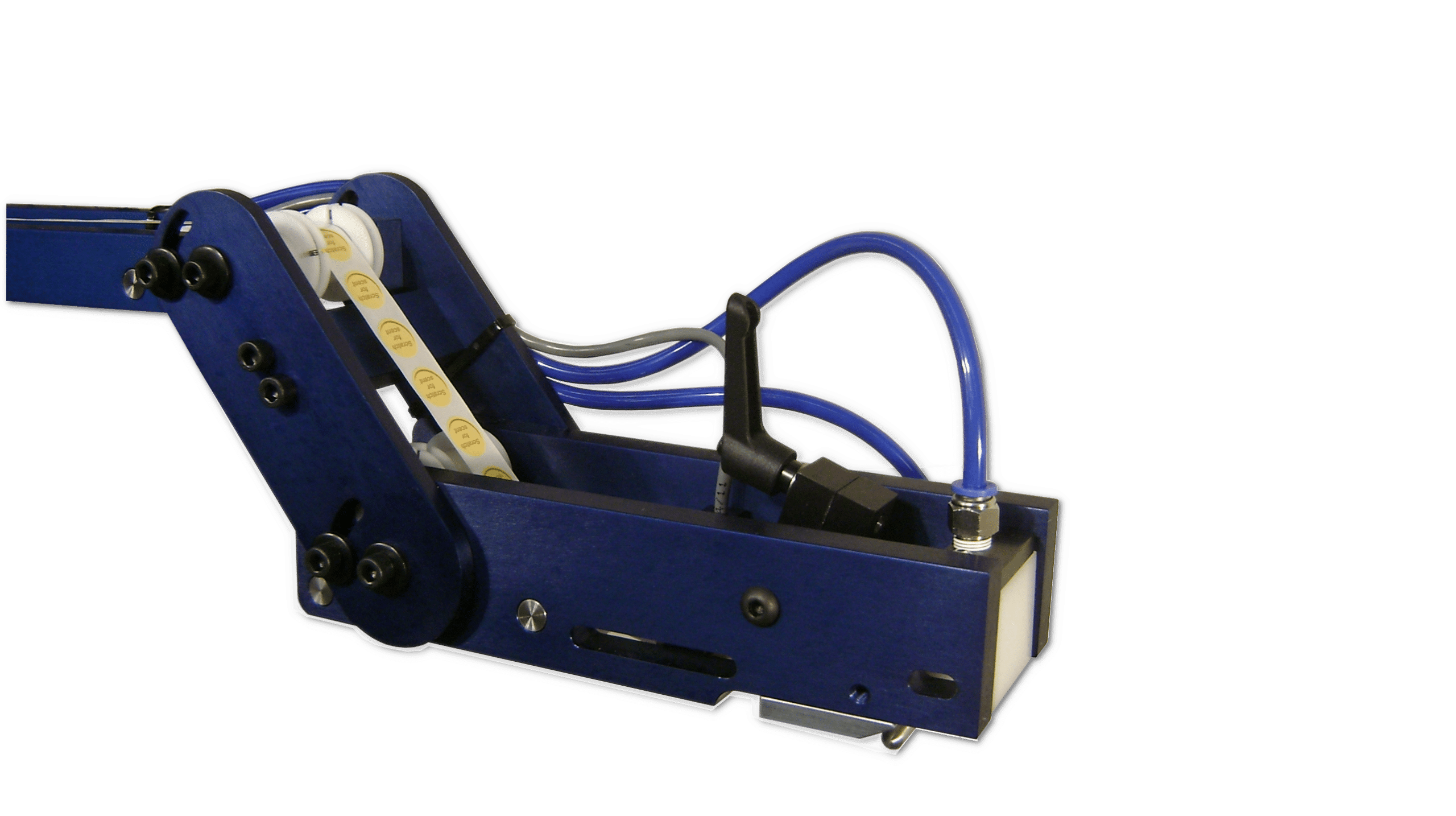

The LabelMill LM3606 is a versatile print-and-apply label machine built for entry-level automation, offering reliable and adaptable labeling solutions for a wide range of production environments. It prints and applies labels at speeds up to 16 inches per second and supports various application methods—like such as tamp, blow-on, corner wrap, and flag modules—for products including boxes, pouches, bottles, and pallets. With a compact design, user-friendly interface, and support for thermal transfer and direct thermal printing, it’s ideal for mid to high-volume labeling operations.

Benefits:

Labeling equipment such as the LM3606 offers cost-effective automation, enhancing labeling efficiency with print-and-apply capabilities for barcodes, expiration dates, sequential numbering, and other variable data. Its flexible design supports multiple application methods and diverse product types, making it an ideal solution for mid to high-volume operations that require reliable and easy-to-use labeling equipment.