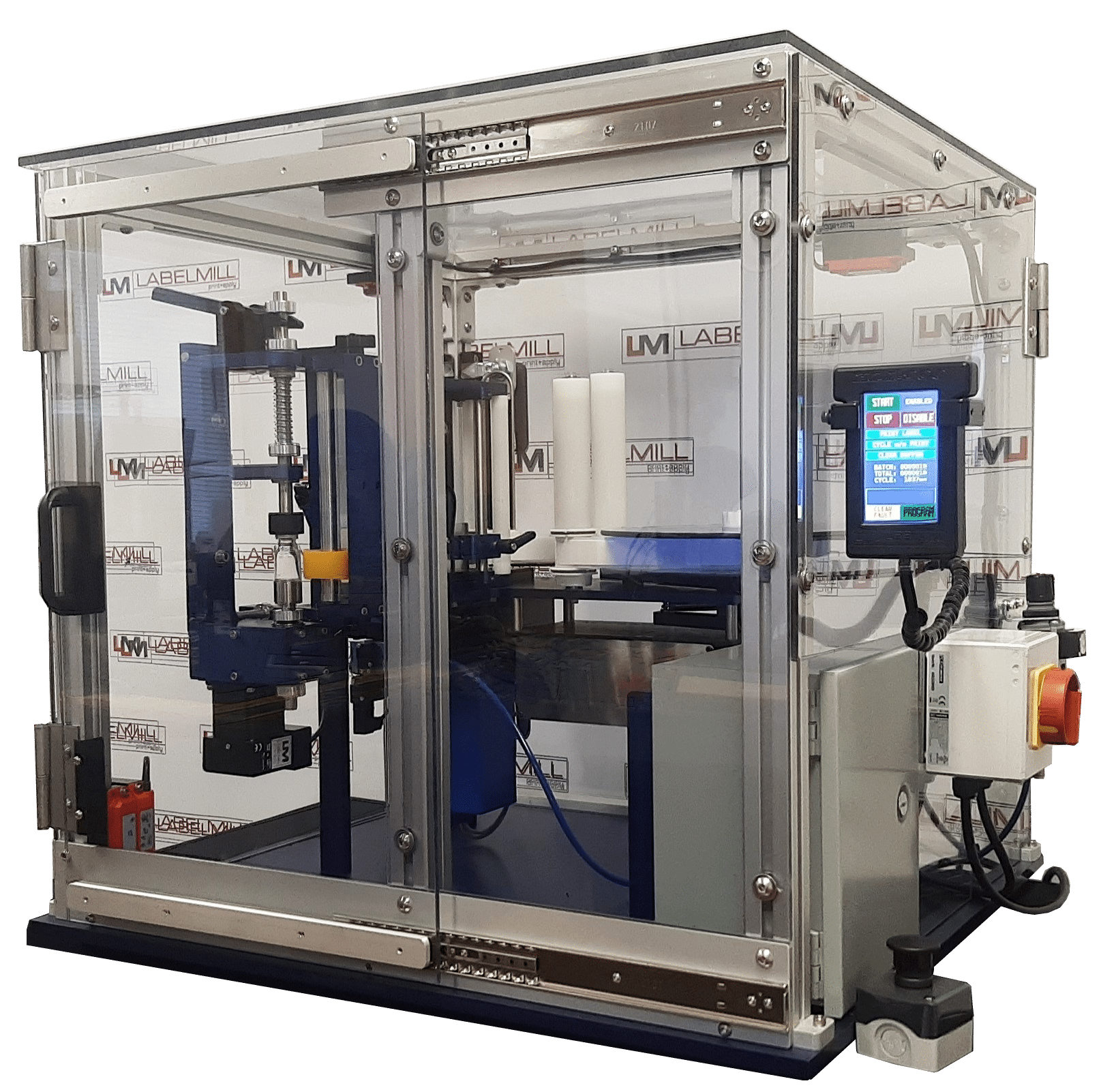

Custom Solutions From Concept To Creation

How It Works

When do you need a custom solution vs. a standard applicator?

The LabelMill standard label applicator is often the best choice for common labeling tasks such as applying labels to standard products. These systems are cost-effective, quick to implement, and proven across a wide range of industries. A custom solution becomes necessary when your product, packaging, or production line has unique requirements—such as unusual shapes, multiple label placements, specialized material handling, or integration into existing automated systems.

What does the typical process for obtaining a custom solution look like?

The process begins with a discovery phase where we review your application requirements, product samples, and production goals. From there, our engineering team designs a tailored system to meet your specifications. All solutions are tested in-house with your product samples, and prepared for your production environment..

What is the installation and integration process?

Depending on the complexity of the system, installation can be as simple as placing the unit at your production line or as involved as a full turnkey integration. Our technicians can install on-site, coordinate with your line integrators, and ensure the applicator is calibrated for your products.

What ongoing support or service is offered after installation?

LabelMill provides ongoing service and support to keep your system running smoothly. This includes phone and remote troubleshooting, access to replacement parts, and on-site service when needed. Our team is committed to supporting you long after installation, ensuring maximum uptime and performance of your labeling equipment.

Serving Multiple Industries

Versatile Product Applications

Drum Label Applicator

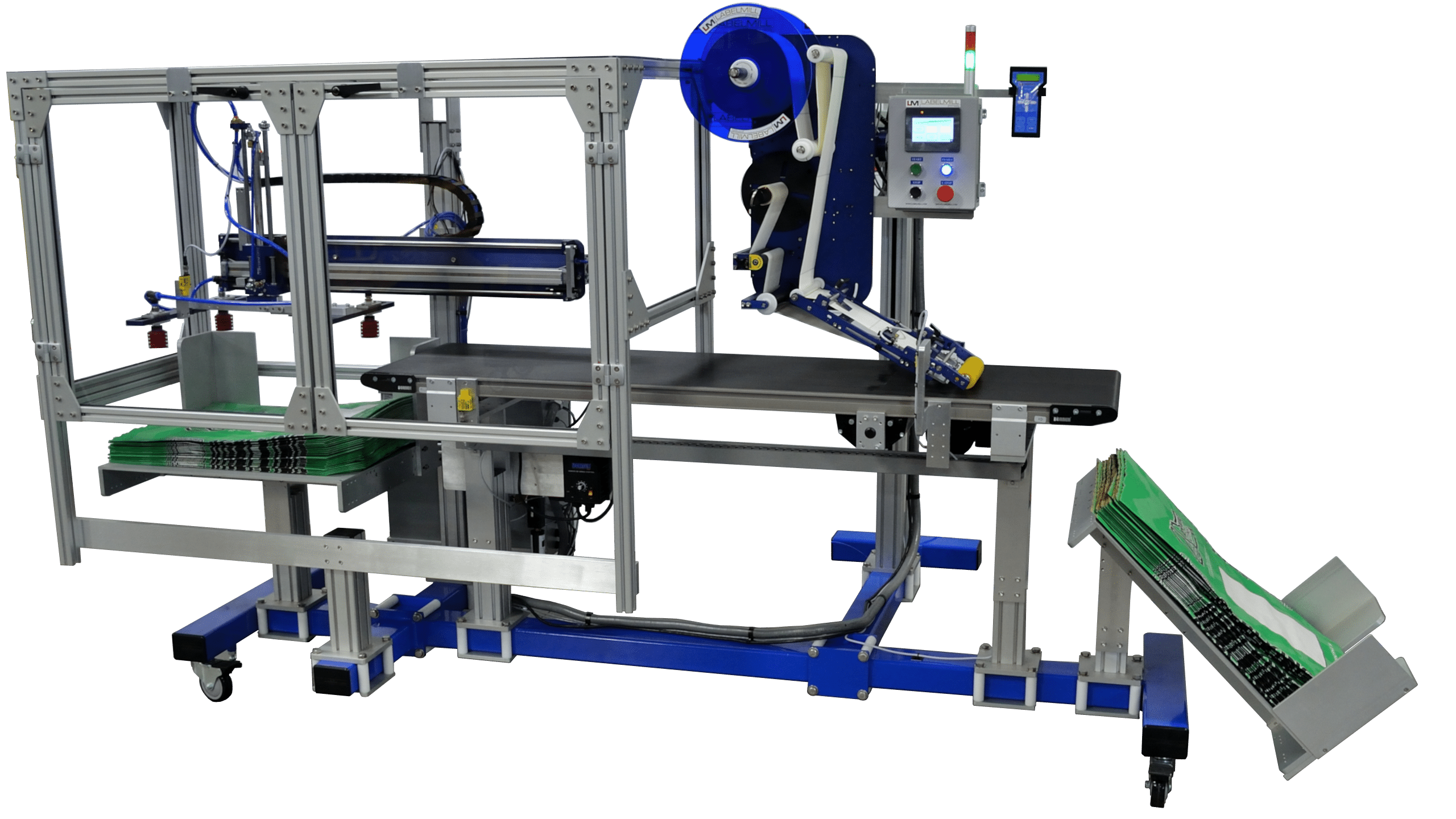

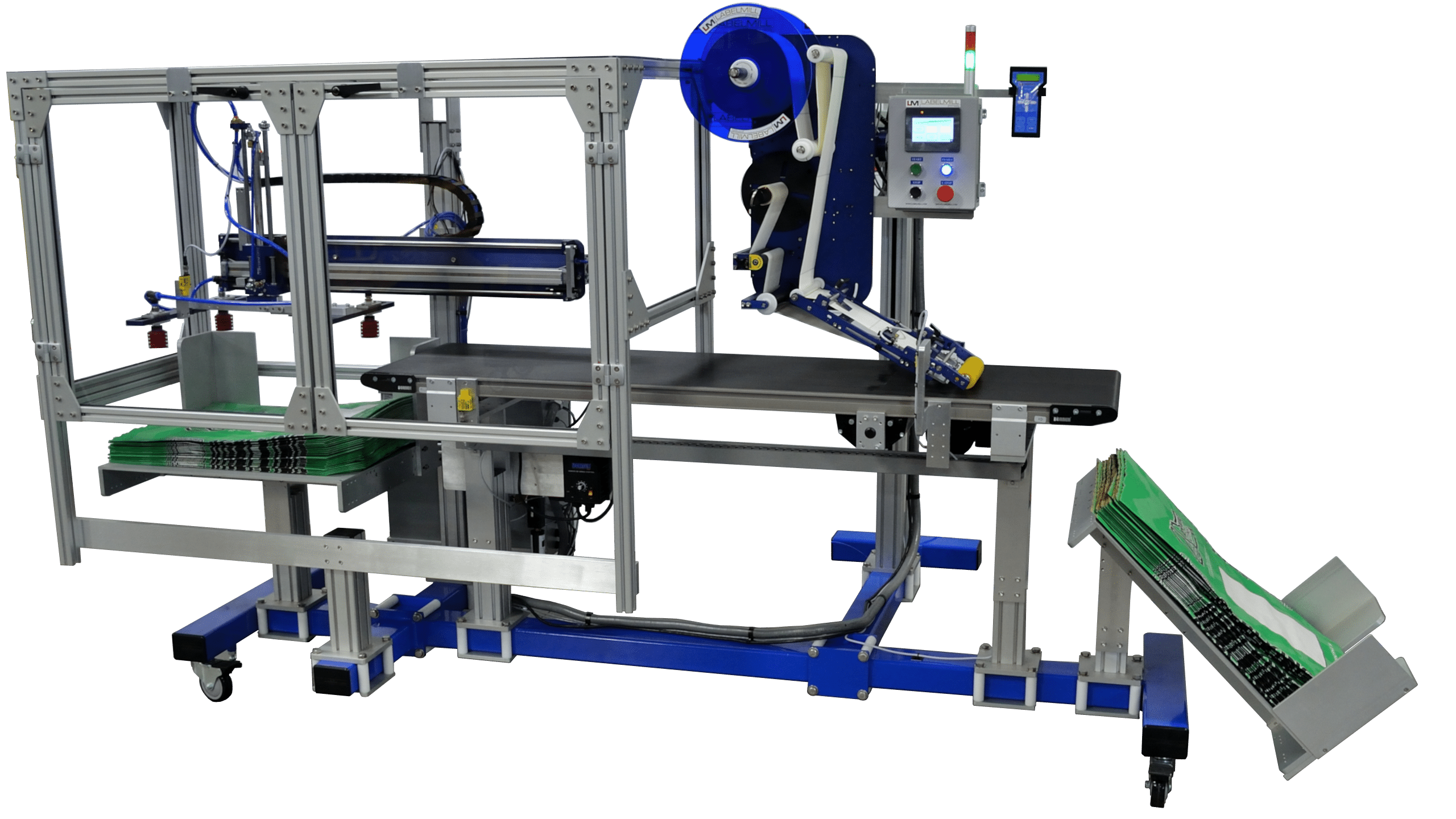

Large Bag Feeder

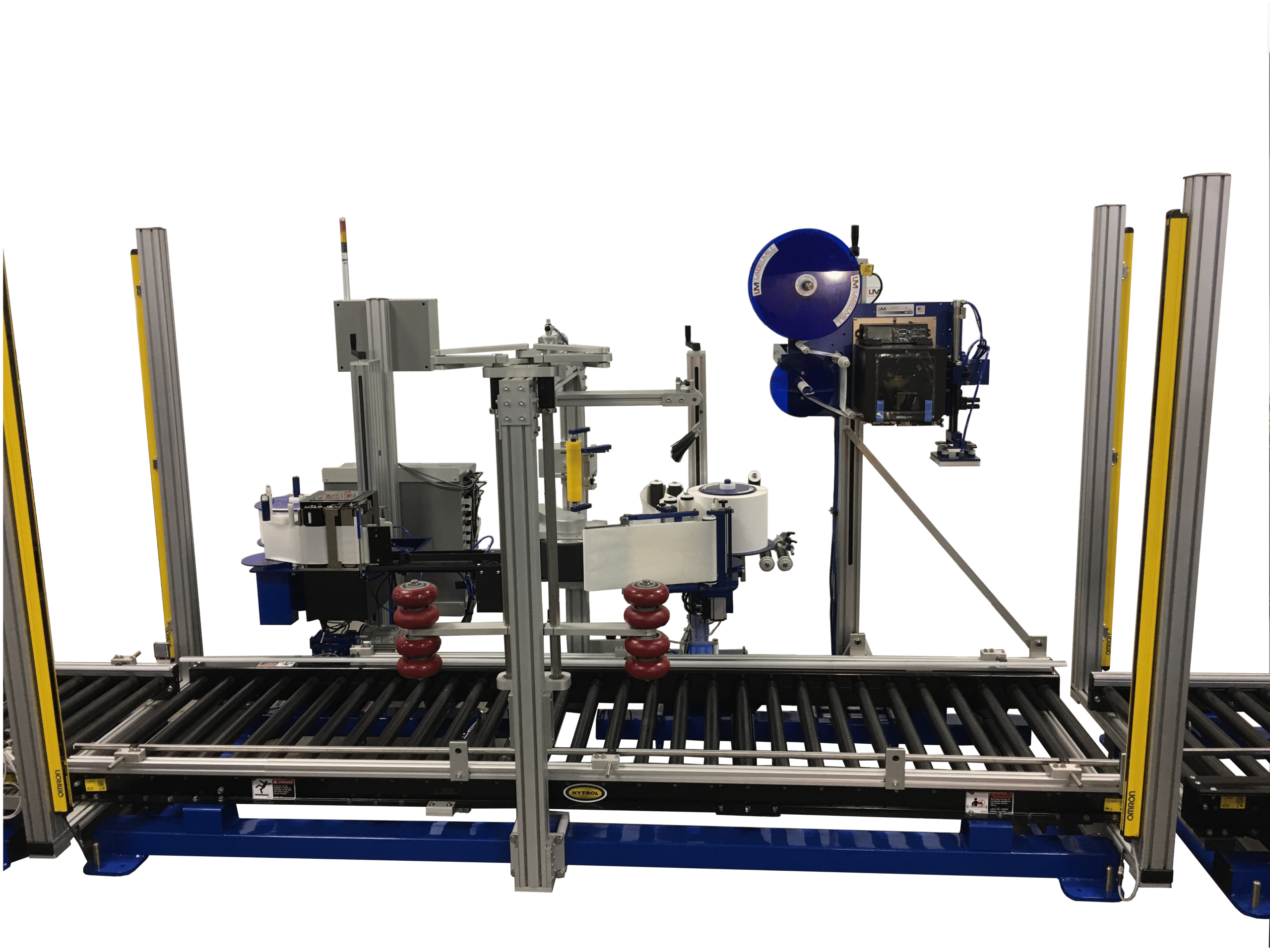

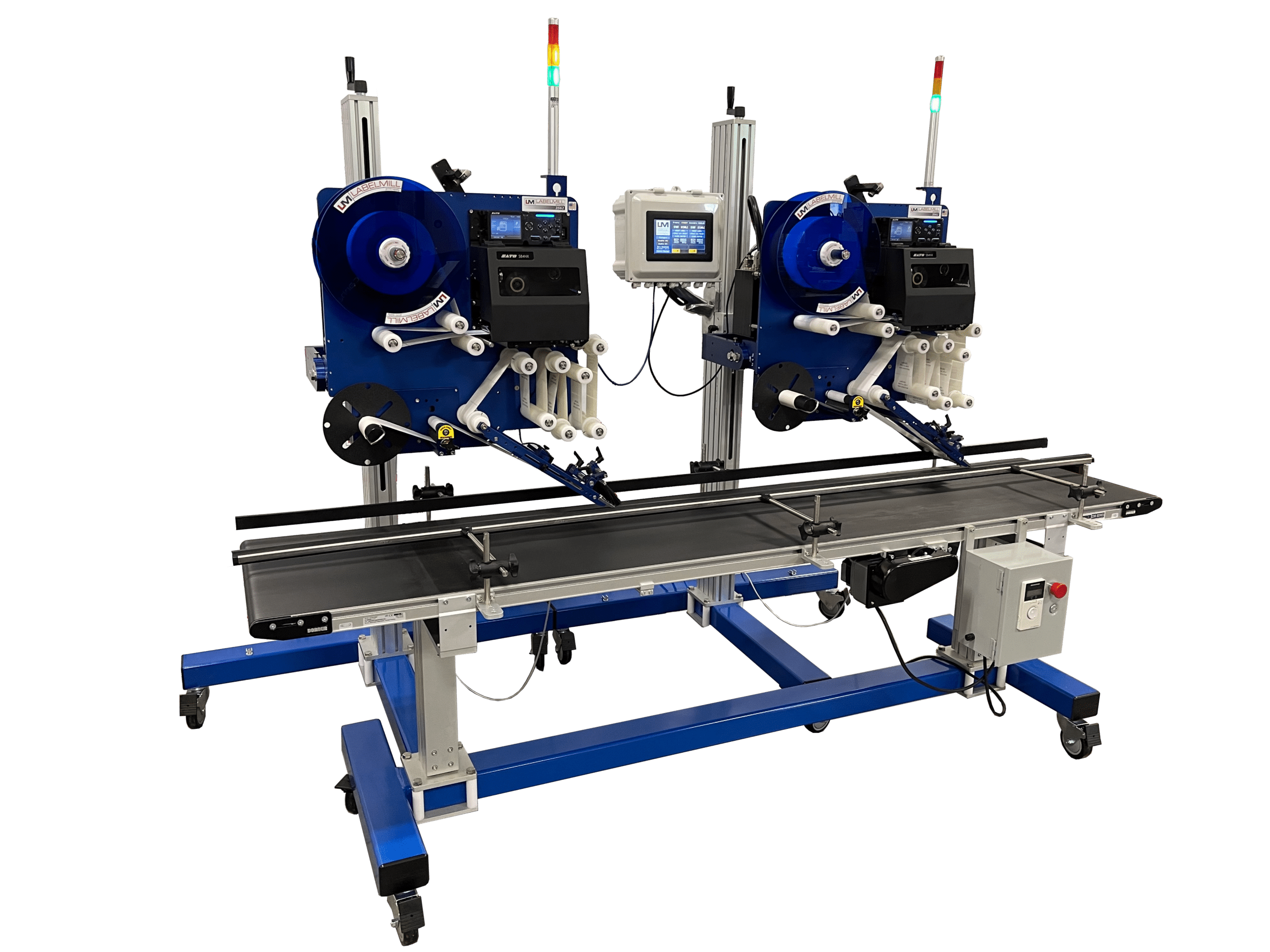

LM3562 Zero Downtime

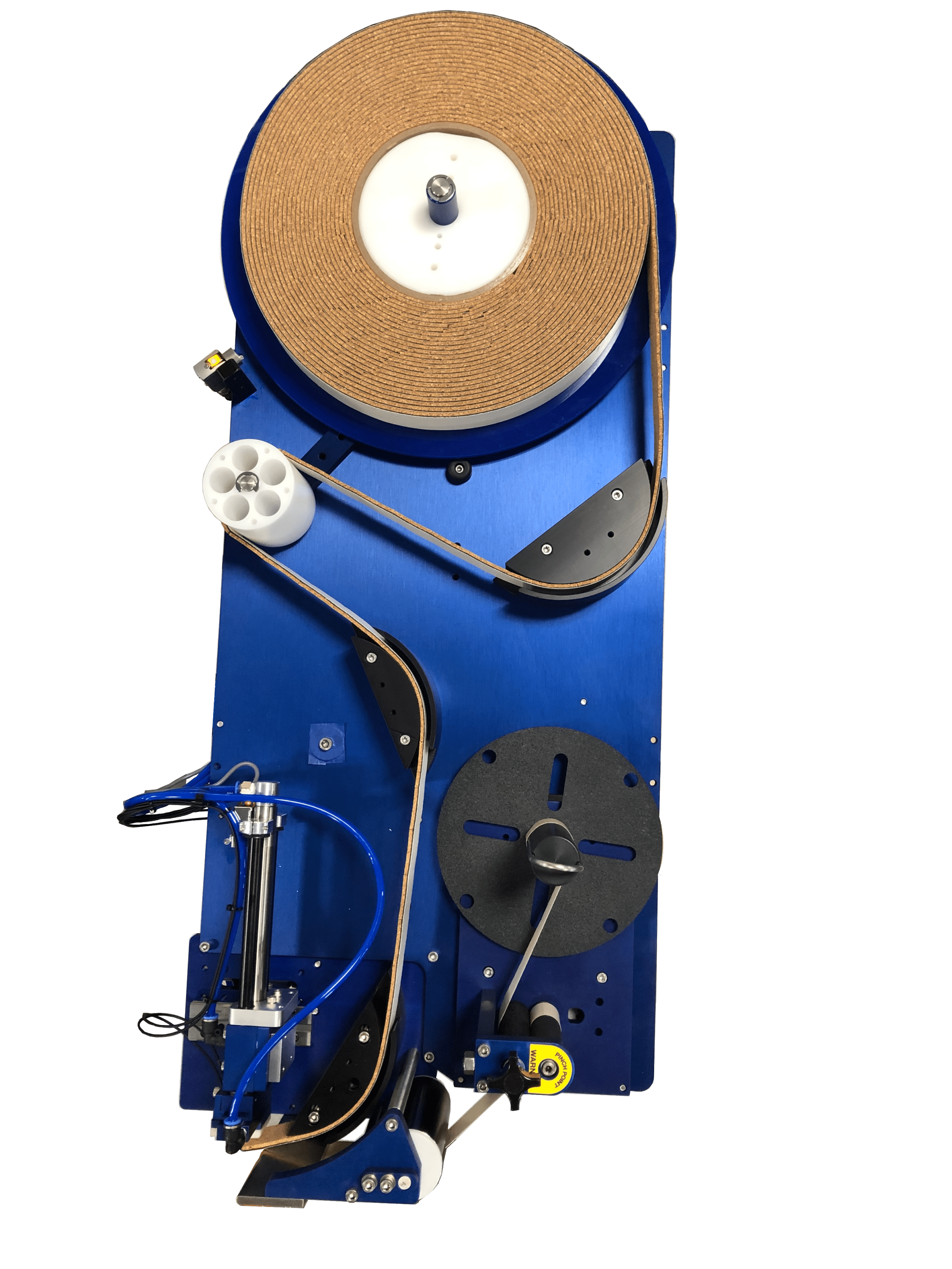

Cork System

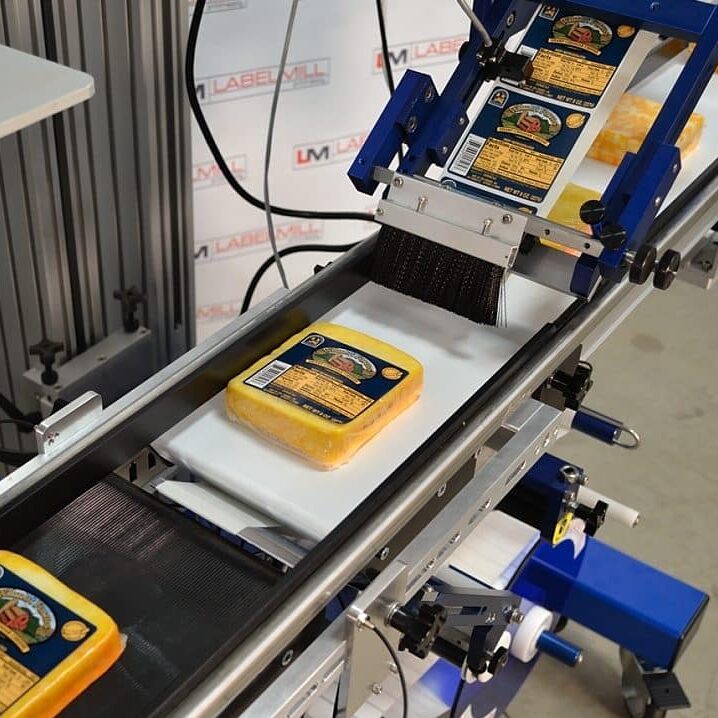

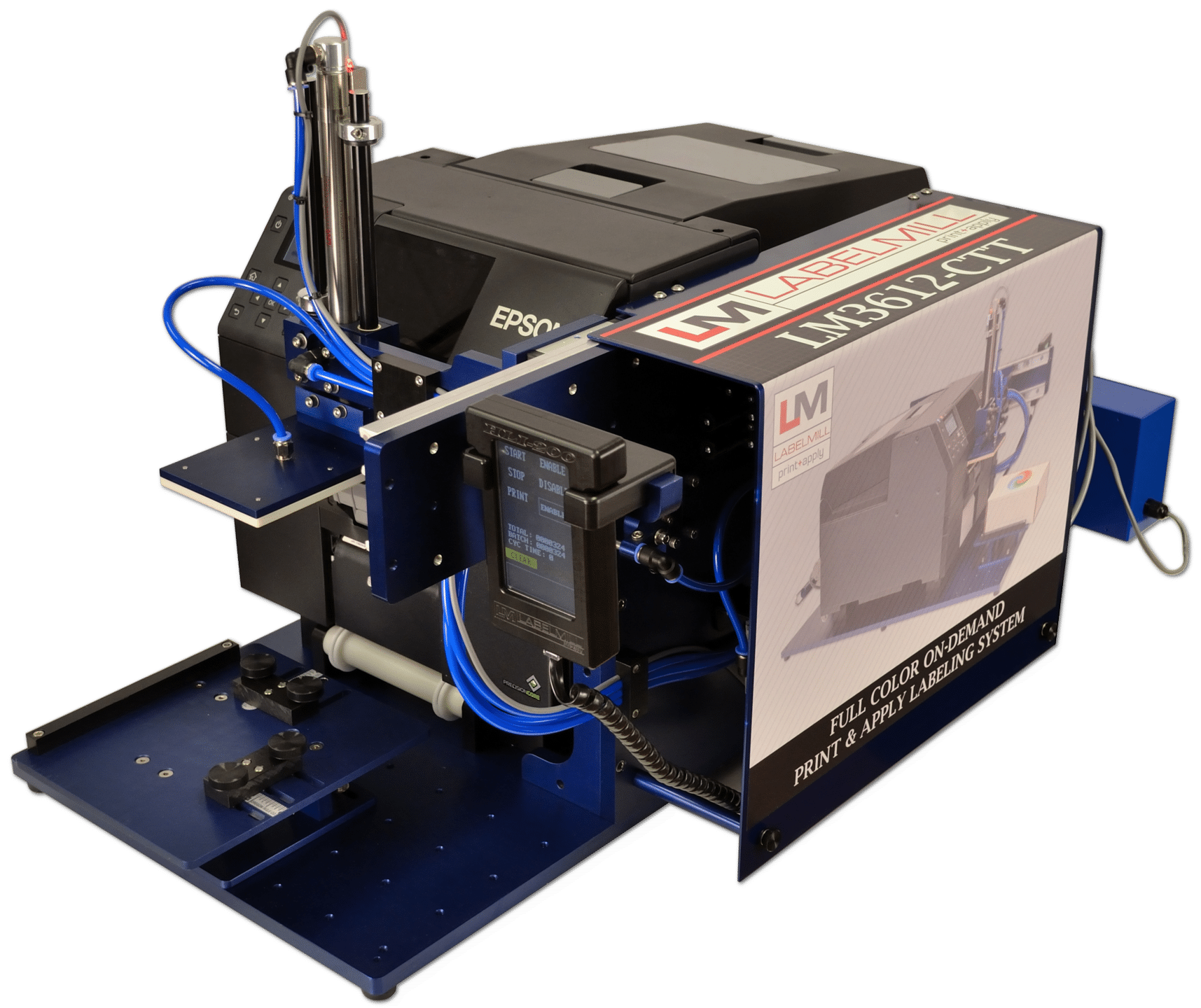

LM3612CTT Tamp

Upright Vial System