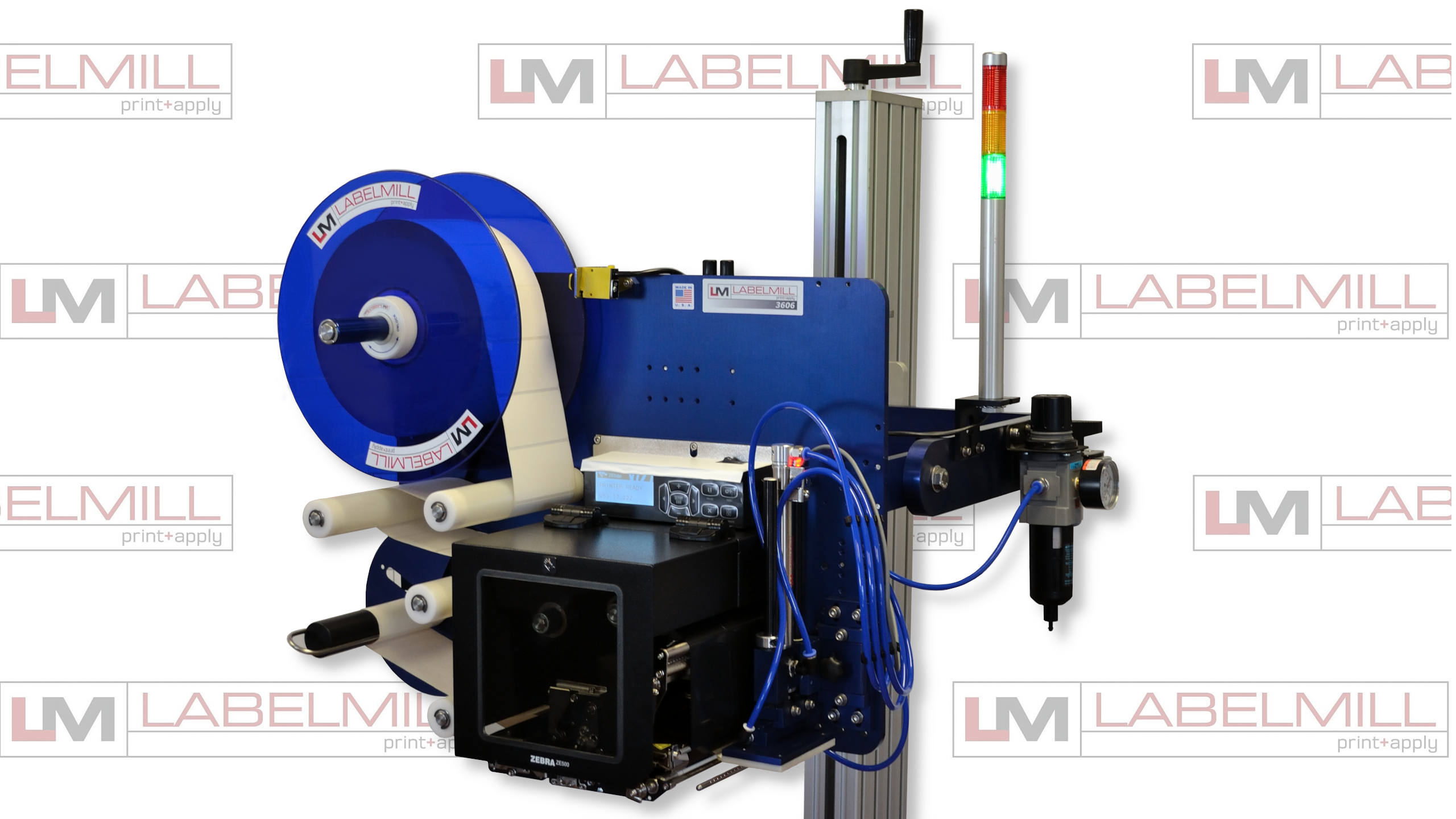

LM3612 - Smart Tamp Print & Apply Pallet Labeling System

LM3612 - Custom Corner-Wrap Print & Apply

LM3612 - Tamp Applicator Labeling System

The LabelMill 3612 is the perfect solution for your print and apply application with print widths up to 6.6” , 15 I/O points and high throughput capability, the 3612 can handle all your print and apply needs!

USE CASES

- Easy integration to scales

- Bar-code scanners

- Product diverters

- Automatic machines

- Conveyor lines

- Remote trigger

- Second trigger for variable data

- Tamp synchronization

- Indicator signals

• Low label

• Broken web

• Batch done

• And more

PRODUCT SPECS

Labeling Speed/Rate: Up to 16” per second and, depending on label and product size, approximately 10 to 90 per minute

Print Method: Thermal transfer and direct thermal

Interface: Centronics parallel, RS-232c Serial, Ethernet, Wireless, USB

Application Method: Tamp is standard, Wipe-on, flag, blow, corner-wrap, and swing tamp are optional

Bar Codes: UPC-A, UPC-E, EAN-8, EAN-13, CODE 3912/5, CODE 128, CODABAR, MSI, 2/5,

CODE 93, UPC Bookland, Matrix 2/5, POSTNET, UCC/EAN 128, PDF-417, Maxicode, Data Matrix

Bar Code Ratios: 1:2, 1:3, 5:2

Interface Sensors: Product sensor-photo eye/limit switch/PLC input

Auxiliary output with connector standard

Electrical: 115 VAC/60Hz - 250 W idle, 600 running

Human Readable Fonts: 12 proportional and mono-spaced fonts including OCR-A and OCR-B

representations and an outline font. American and European characters, uppercase and lower case with descenders (code table 850)

Air Requirements: 80 psi/3 cfm when equipped with tamp, flag, blow, swing, or corner wrap

Environment: Operating 50-95° F (10-35° C)

15-85% RH, non-condensing

Label Size: Minimum 1” wide x 1/2” long

General Size: 25”W x 22”D x 21”H

Weight: 61 lbs. with u-arm

Label Roll Capacity: 12” maximum outside diameter wound on a 3” I.D. core. Die-cut waste removed with minimum of 1/8” separations between labels in running direction.

Options: Variety of print engines, left-hand models, alarm, upgrade for longer labels, power unwind for larger spools.

INCLUDED FEATURES

- Heavy Duty Industrial Design

- 12 Inch Label Storage Spool Standard

- Swing Away Tamp Assemble

- User-Friendly Operating Software

- Batch Counter

- Job Storage

- Printer Status Outputs

- Left and Right-Hand Designs

- 15 Auxiliary I/O Points (Factory Programmable)

- Hand Held User Interface

OPTIONAL FEATURES

- Dual Trigger Inputs

- Encoder Port / Conveyor Interface

- Ethernet Interface (Factory Programmable)

- Optional Width of 6.5” x 8.5”

- Power Unwind Label Storage Spool

- Serial Port Communication

- Serial Port Communication

- Smart Tamp

- Tandem Labelers / Zero Down Time

- Touch Screen Interface

LabelMill offers a variety of labeling solutions, including: Flag Label applicator, Print and Apply Label Machine, Label Application Machine, Sticker applicator machine, labeling system, pallet label applicator, label applicator, flag label applicator, automatic label applicator machine, automatic box labeling machine, pallet label applicator, label printer applicators, print and apply labeler, automatic sticker labeling machine, bottle labeling equipment, industrial labeling machine, pressure sensitive label applicator, product labeling machine, labeling equipment manufacturers, labeling solutions, label applicator, labeler, label solution, print and apply, print & apply, box labeler, label system, automatic label applicator machine, product label, product labeling, automatic labeling, primary labeling, primary label, fully automatic label, custom label applicator, custom label, pallet label applicator, bottle labeling, tube labeling, easy label applicator, label printer applicator, print and apply labeler, print & apply, print & apply label applicator